Desde pontes e estruturas de edifícios a fixadores, electrodomésticos e painéis para automóveis, o aço galvanizado é amplamente utilizado porque o revestimento de zinco retarda o ataque ambiental e corrói preferencialmente onde o substrato está exposto.

Este blogue, apresentado por Weijunli Steel, um líder no fornecimento e transformação de aço, O livro explica como funcionam os revestimentos de zinco, compara os principais métodos de galvanização, descreve as normas de desempenho e de ensaio e fornece orientações práticas para especificar e adquirir o produto galvanizado adequado para o seu projeto.

Definição de aço galvanizado

O aço galvanizado é o aço que é coberto ou revestido com zinco para evitar a sua corrosão. O revestimento de zinco constitui uma barreira física e um ânodo de sacrifício. Quando o revestimento é riscado ou cortado, o zinco corrói preferencialmente e serve de barreira para o aço que está por baixo. A dupla proteção do revestimento e do zinco de sacrifício faz do aço galvanizado um sistema de proteção contra a corrosão rentável e amplamente utilizado na construção, infra-estruturas, peças automóveis, aparelhos e ferragens.

Como é que os revestimentos de zinco protegem o aço

O zinco oferece proteção de duas formas distintas. Em primeiro lugar, o revestimento de zinco cria uma barreira física aos elementos corrosivos (água, oxigénio, sais) que, de outra forma, atingiriam o aço. Em segundo lugar, o zinco é mais ativo electroquimicamente do que o ferro: em arestas expostas ou defeitos, o zinco corrói, fornecendo proteção catódica ao substrato de aço. Este comportamento de sacrifício é particularmente vantajoso no caso de danos mecânicos ou de cortes no terreno, em que o metal de base tenha sido exposto.

Principais métodos de galvanização

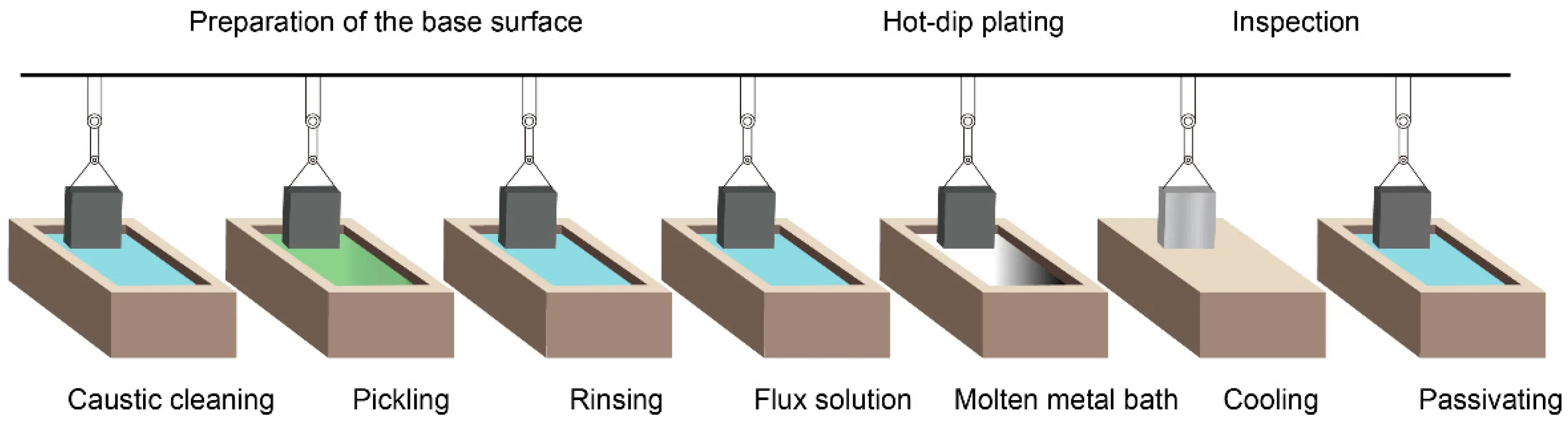

Galvanização por imersão a quente (HDG)

A galvanização por imersão a quente é o método clássico e mais robusto. As peças de aço fabricadas ou as bobinas contínuas são limpas (desengorduradas e decapadas), fundidas e depois imersas num banho de zinco fundido (≈450°C). As reacções químicas na interface formam várias camadas intermetálicas de zinco-ferro encimadas por uma camada de zinco relativamente puro. Os revestimentos HDG são relativamente espessos e robustos - ideais para elementos estruturais, equipamento de exterior e tudo o que exija uma longa vida útil em ambientes agressivos.

Prós: revestimento espesso e durável; excelente proteção de sacrifício; bom para grandes artigos fabricados.

Contras: acabamento superficial mais grosseiro (spangle), dimensões ligeiramente mais grossas, necessidade ocasional de pós-tratamento.

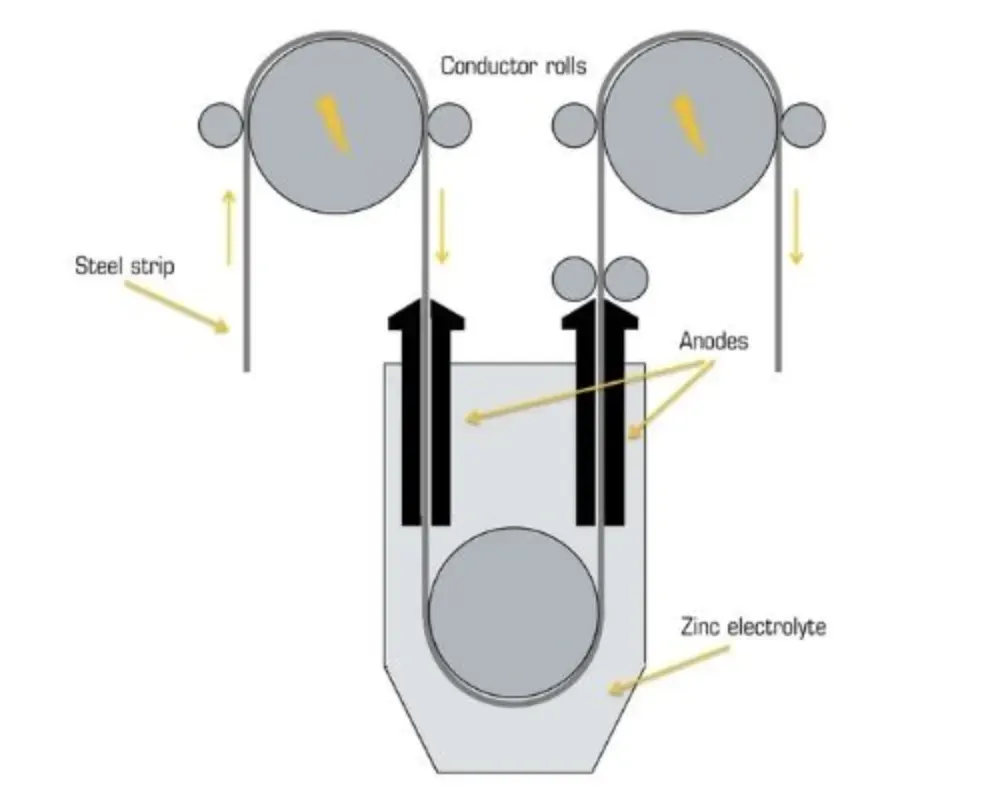

Electrogalvanização (EG)

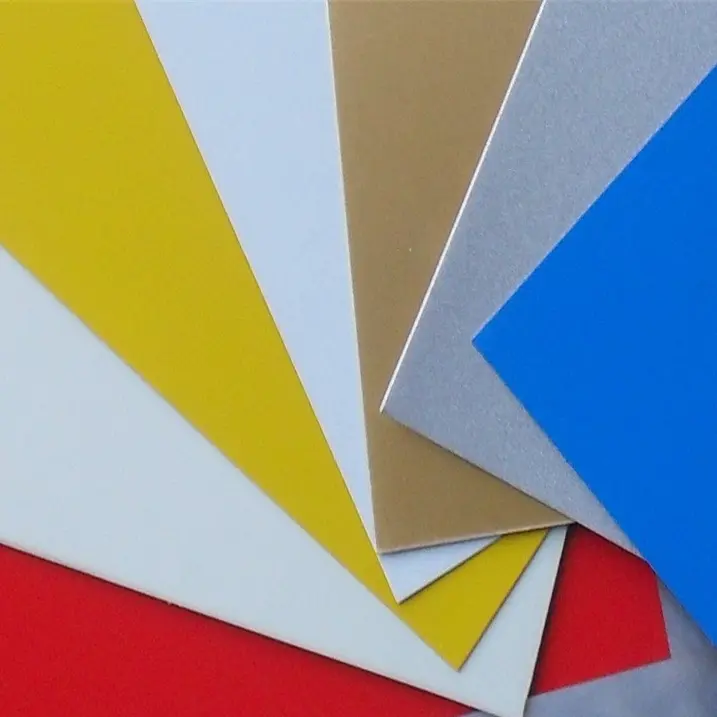

A electrogalvanização deposita zinco de um banho eletrolítico em chapas e tiras à temperatura ambiente. O revestimento é mais fino e mais suave do que o HDG e proporciona uma superfície atractiva para pintura e moldagem. O EG é amplamente utilizado para painéis de carroçaria de automóveis e aparelhos onde a qualidade da superfície é crítica.

Prós: acabamento liso e brilhante, tolerâncias apertadas, excelente capacidade de pintura.

Contras: revestimento mais fino → menor vida útil de sacrifício do que o HDG, normalmente utilizado em interiores ou onde é aplicada pintura.

Outros métodos (breve)

- Galvanneal: O zinco por imersão a quente é recozido para formar uma superfície de liga de zinco-ferro que adere muito bem à tinta.

- Xeretagem / difusão térmica: Útil para pequenos fixadores e peças que requerem revestimentos finos uniformes.

- Revestimentos de flocos de zinco: Revestimentos multicamadas não electrolíticos para fixadores de alto desempenho e componentes automóveis.

Especificações e normas de revestimentos - Como os revestimentos são expressos

A massa do revestimento é a métrica padrão para especificar o desempenho. As notações comuns incluem G30, G60, G90 na prática dos EUA (G = galvanizado), ou gramas por metro quadrado (g/m²) em especificações internacionais. As normas que verá referenciadas incluem ASTM A123 (galvanização por imersão a quente de artigos manufacturados), ASTM A653/A792 (produtos de chapa revestida), ISO 1461, e EN equivalentes. Aquando da especificação, indicar sempre o método (HDG/EG), a classe de revestimento (g/m² ou G#), o grau do substrato e os eventuais pós-tratamentos (lubrificação, pintura).

Desempenho: Resistência à corrosão e vida útil prevista

A vida útil efectiva do aço galvanizado é afetada pela massa do revestimento, pelo ambiente (rural, urbano, industrial, marítimo), pela conceção (permite a drenagem e evita a humidade retida pela chuva) e pela manutenção. Como regra geral:

Os revestimentos HDG mais espessos (elevado g/m²) em ambientes rurais ou urbanos podem durar décadas de serviço.

Os painéis EG com sistemas de pintura têm um bom desempenho quando o aspeto da superfície e a proteção contra a corrosão são questões importantes.

Em ambientes marinhos corrosivos ou químicos, um sistema duplex (galvanizado + pintura ou revestimentos especiais) ou aço inoxidável pode ser a melhor opção.

Tenha sempre em conta o custo do ciclo de vida (custo inicial do material + manutenção) e não apenas o primeiro custo.

Considerações sobre mecânica e fabrico

Os revestimentos galvanizados influenciam a conformação, a soldadura e a união:

- Formação: Tanto o HDG como o EG podem ser formados, mas o retorno elástico e a fissuração dos bordos devem ser avaliados. O revestimento fino e uniforme do EG é geralmente melhor para estiramentos apertados.

- Soldadura: O vapor de zinco pode criar riscos de fumos de soldadura; siga os procedimentos de ventilação e de soldadura. O revestimento na zona de soldadura será consumido; aplicar reparação adequada ou proteção contra a corrosão após a soldadura.

- Fixação: Utilizar fixadores compatíveis e isolamento nos locais de contacto de metais diferentes para evitar a corrosão galvânica.

Controlo de qualidade e testes

Exigir certificados de moagem e relatórios de teste para compras críticas. Os testes típicos de CQ incluem:

- Medição da espessura do revestimento (medidores magnéticos ou de correntes de Foucault).

- Ensaios de névoa salina (ASTM B117 / ISO 9227) para o rastreio comparativo.

- Ensaios de aderência e de flexão para garantir a integridade do revestimento após a moldagem.

- Inspeção visual para uniformidade, defeitos de ângulo ou porosidade.

Insista nos Certificados de Ensaio de Moagem (MTC) associados a números de calor ou de lote para efeitos de rastreabilidade.

Lista de controlo das aquisições - O que especificar

Quando encomendar aço galvanizado, certifique-se de que especifica o seguinte:

- O método de galvanização (HDG vs EG);

- A classe de revestimento (g/m² ou G#);

- Norma aplicável (ASTM/EN);

- Grau e espessura do aço do substrato;

- Acabamento da superfície > (oleada, passivada, espelhada);

- Embalagem/manuseamento> documentação de ensaio necessária (MTC, relatório de espessura do revestimento, dados de pulverização salina, se aplicável);

Para conjuntos soldados ou fabricados, especificar se a especificação pós-galvanização ou pré-galvanização é aplicável e quaisquer procedimentos de retoque.

Melhores práticas de instalação e manutenção

A conceção correta da drenagem e do fluxo de ar reduzirá a possibilidade de a humidade ficar retida. Uma vez protegidas as arestas cortadas com tinta rica em zinco ou sprays de galvanização a frio, os metais diferentes não devem ser deixados em contacto direto entre si; quando em contacto com a humidade, criam uma célula galvânica, a menos que os dois metais estejam isolados eletricamente.

Se forem pintadas, efetuar um pré-tratamento nas superfícies galvanizadas para melhorar a aderência da tinta, como a aplicação de um fosfato de zinco. A inspeção regular das áreas danificadas e a reparação imediata dos danos prolongam substancialmente a vida útil.

Conclusão

Aço galvanizado continua a ser a pedra angular da proteção contra a corrosão em todas as indústrias devido à barreira combinada do zinco e à proteção sacrificial. A seleção do método de galvanização, da classe de revestimento e dos detalhes corretos para o ambiente optimizará o tempo de vida útil e o custo total

Sobre a Weijunli Steel

Como fornecedor e transformador profissional de aço, A Weijunli Steel opera linhas de produção avançadas e sistemas de controlo de qualidade rigorosos para garantir que cada aço galvanizado por atacado (bobina, tira, folha, placa) cumprem as normas internacionais. A nossa equipa técnica apoia os parceiros globais com personalização flexível e entrega rápida.

Escolha o nosso serviço grossista e solução personalizada em aço galvanizado, e obterá produtos de primeira qualidade a preços competitivos.