O corte longitudinal de bobinas de aço converte as bobinas principais em tiras de tamanho exato para a formação de rolos, estampagem, fabrico de tubos e outros processos a jusante.

Como fornecedor grossista de aço, A Weijunli Steel tem o prazer de explicar toda a sequência de corte longitudinal em linhas modernas, destacar parâmetros técnicos críticos e dar recomendações práticas que as equipas de aquisição e engenharia podem utilizar ao especificar o material de corte longitudinal.

O que é o corte longitudinal de bobinas de aço?

O corte longitudinal de bobinas de aço é um processo de corte longitudinal em que uma bobina de aço larga é dividida em várias tiras mais estreitas utilizando facas rotativas e, em seguida, enrolada novamente. Ao contrário das operações de corte longitudinal, o corte longitudinal centra-se na precisão da largura, na qualidade dos bordos e no controlo da tensão. As tiras de aço resultantes são mais fáceis de manusear, mais adequadas a equipamentos automatizados e optimizadas para requisitos específicos de utilização final.

Processo de corte passo a passo (fluxo de trabalho prático)

Segue-se o fluxo de trabalho completo de corte de bobinas de aço, alinhado com linhas de produção reais e habitualmente observado em operações de corte industrial.

1. Carregamento da bobina (carregamento do desbobinador)

A bobina é colocada no desbobinador por grua ou empilhador.

Os operadores devem verificar a compatibilidade do diâmetro interior, confirmar a orientação da bobina e fixar a bobina utilizando mandris ou anéis de bloqueio, verificando simultaneamente o número de calor e a identificação da bobina para manter a rastreabilidade ao longo da produção.

2. Desenrolamento

O desbobinador expande-se para suportar o ID da bobina e a tira é introduzida na linha.

Durante o arranque, a velocidade da linha e a tensão posterior são aumentadas gradualmente, ao mesmo tempo que se monitoriza a excentricidade e a estabilidade da bobina para evitar a telescopagem, o colapso dos bordos ou uma folga súbita.

3. Enfiamento / Introdução

A cabeça da tira é guiada para a linha manualmente ou por um sistema de enfiamento automático.

O corte correto da cabeça e a fixação temporária garantem um avanço suave, protegem os gumes das facas durante o engate inicial e reduzem o risco de desalinhamento da tira.

4. Nivelamento / Endireitamento

Um nivelador de rolos múltiplos elimina as tensões internas e o jogo de bobinas residual.

As folgas do rolo e a força de nivelamento são ajustadas de acordo com o calibre e o grau do material, produzindo uma tira plana que suporta um controlo de largura consistente e um desempenho de corte estável.

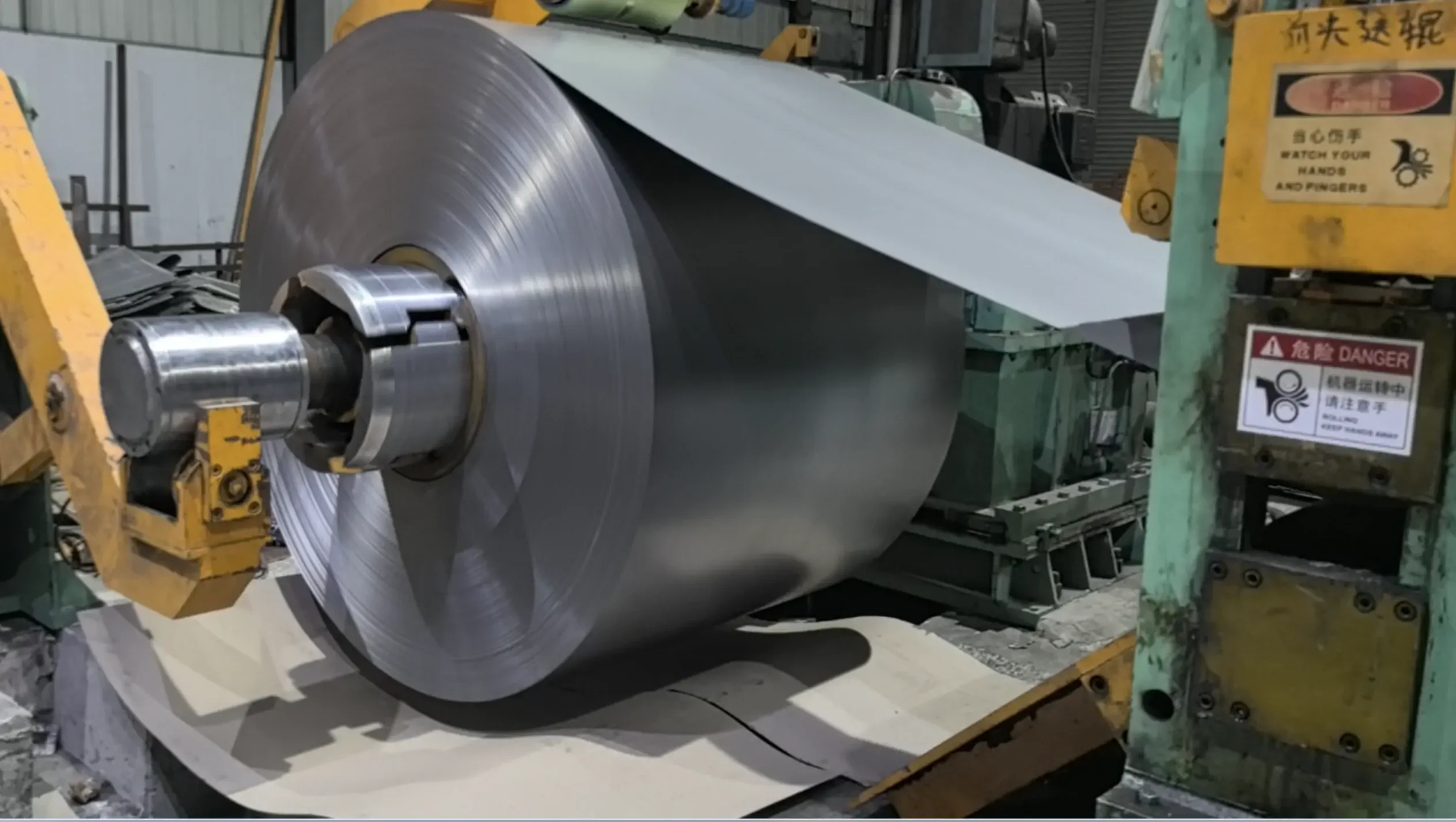

5. Corte

Esta é a parte essencial do processo de ensilagem de bobinas de aço. As facas rotativas superiores e inferiores efectuam os cortes longitudinais que definem as larguras finais das tiras.

O espaçamento da lâmina, a folga da lâmina e a velocidade de corte são definidos com base na espessura e dureza do material, enquanto o estado da lâmina e o arrefecimento são monitorizados para minimizar a altura da rebarba e a deformação da aresta.

6. Enrolamento de sucata

Os bordos de desperdícios aparados são enrolados separadamente em bobinas de desperdícios específicas.

Isto evita que a sucata fique emaranhada com as tiras acabadas, estabiliza a tensão da linha e permite que o peso da sucata seja registado para análise do rendimento e otimização do processo.

7. Tensionamento e separação de bandas

Após o corte, as tiras individuais são conduzidas através de rolos tensores e separadores.

Os sistemas de controlo de tensão em circuito fechado garantem uma tensão uniforme da fita, enquanto os separadores evitam o contacto da fita e reduzem o risco de arranhões na superfície ou problemas de rastreio.

8. Reenrolamento (enrolamento acabado)

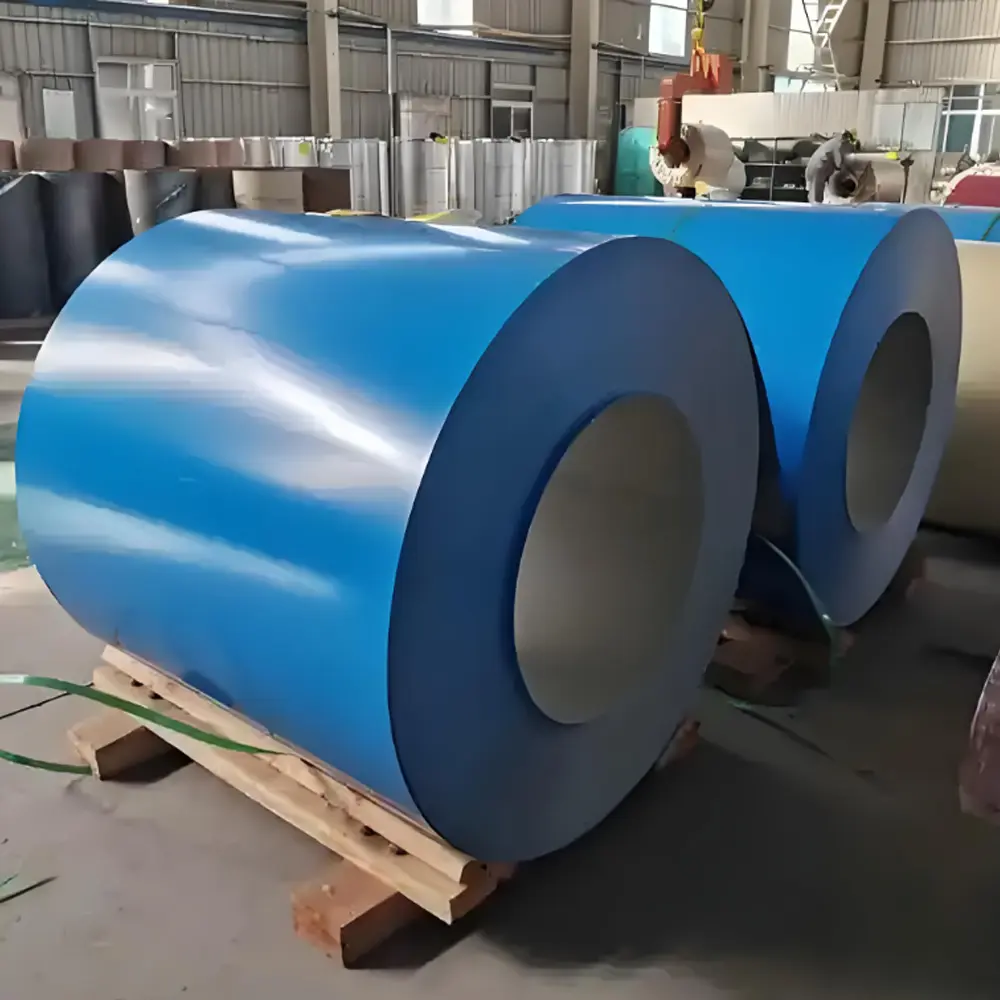

Cada tira de aço é enrolada numa bobina acabada sob um binário controlado.

Os parâmetros do enrolador, como a tensão de enrolamento, a pressão do mandril e o padrão de enrolamento, são ajustados para produzir bobinas concêntricas e bem compactadas que atendam aos requisitos de ID e OD do cliente.

9. Manuseamento de bobinas acabadas e fora de linha

As bobinas acabadas são retiradas do enrolador, pesadas, etiquetadas e preparadas para expedição.

A inspeção final confirma a integridade da bobina, o estado da superfície e a qualidade da embalagem, com películas de proteção ou intercalação aplicadas conforme necessário para evitar danos em trânsito.

Principais parâmetros técnicos que os compradores devem especificar

Para garantir resultados consistentes no corte longitudinal de bobinas de aço, os compradores devem definir claramente:

- Largura e tolerância da tira

- Consistência da espessura e variação do calibre

- Estado da aresta (altura da rebarba, limites de ondulação da aresta)

- Requisitos de curvatura e planicidade

- ID da bobina, OD e peso máximo da bobina

- Estado da superfície e requisitos de proteção

- Normas de embalagem e rotulagem

Defeitos comuns, causas principais e prevenção

Eis os problemas que podem ocorrer aquando do corte de bobinas de aço:

- Rebarbas / arestas rugosas - Folga incorrecta da faca ou lâminas cegas. Prevenir através da manutenção das facas e da regulação correta da folga.

- Camber (curvatura da aresta) - tensão irregular ou nivelamento assimétrico. Evitar através de um controlo adequado da tensão e da configuração do nivelador.

- Onda de borda / danos no corte de borda - tensão de enrolamento ou guias danificadas. Prevenir através do controlo da tensão de enrolamento e da manutenção das guias.

- Bobinas telescópicas / soltas - tensão incorrecta da bobina durante o enrolamento. Prevenir com controlo de binário calibrado e verificações de ajuste do núcleo.

- Arranhões na superfície - manuseamento incorreto, embalagem defeituosa ou detritos estranhos nos rolos. Evitar com películas de proteção, superfícies de rolo limpas e manuseamento cuidadoso.

Insista nos gráficos SPC (controlo estatístico do processo) do fornecedor e nas verificações de aceitação da primeira bobina.

Controlo de qualidade e práticas de ensaio

Um controlo de qualidade robusto durante as linhas de corte de bobinas de aço inclui normalmente

- Inspeção da bobina de pré-fenda (superfície, lubrificação, medição de ID)

- Verificação da primeira faixa: verificar a largura, a espessura, a aresta, a curvatura e a tensão de recuo antes da corrida completa

- Sensores em linha: rastreio de bordos, medidores de tensão, termopares para arrefecimento da faca, se aplicável

- Inspeção final e registos fotográficos de cada bobina acabada

- Documentação rastreável: ID da bobina, número de aquecimento, regulação da máquina e assinatura do operador

Para tiragens críticas, exigir peças cortadas de amostra e ensaios de produção antes da aceitação do volume total.

Considerações do comprador e logística

No fornecimento de tiras de aço cortadas, como fornecedor grossista de aço, A nossa empresa ajuda os clientes a equilibrar os requisitos técnicos com a eficiência de entrega.

- MOQ e rendimento: O corte longitudinal de bobinas de aço gera o corte de bordas. Esclarecemos as larguras mínimas de corte e fornecemos estimativas de rendimento com base na disposição das bobinas.

- Prazo de entrega: Os horários de corte e a configuração das facas podem afetar a entrega. Os tamanhos críticos podem ser planeados com antecedência para um fornecimento estável.

- Compatibilidade do equipamento: A identificação, o diâmetro externo e o peso da bobina são confirmados para corresponder ao equipamento de desenrolamento do cliente.

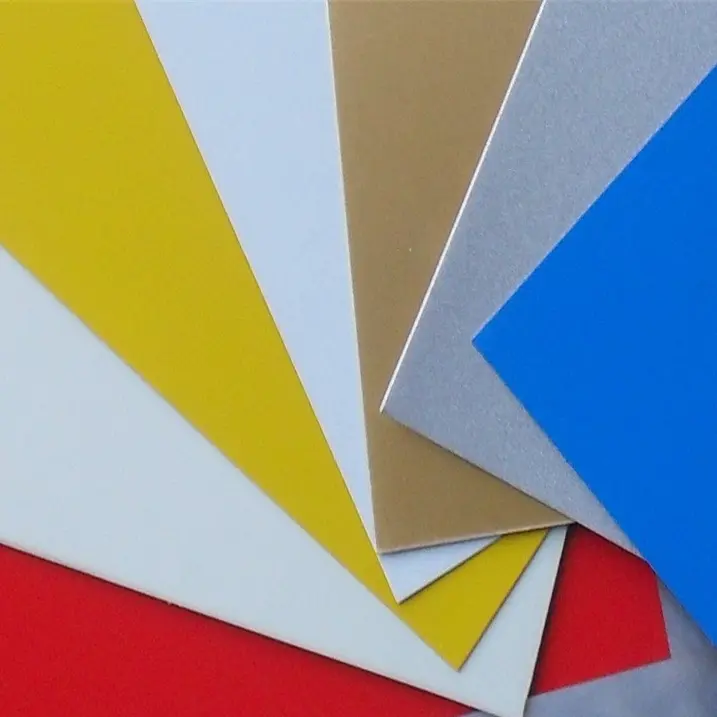

- Embalagem: A película protetora ou a intercalação estão disponíveis para tiras pintadas ou pré-revestidas; a proteção contra a humidade pode ser adicionada para o transporte a longa distância.

- Capacidade de processamento: As nossas operações de corte longitudinal seguem uma configuração normalizada das facas e verificações durante o processo para garantir uma largura consistente e uma qualidade dos bordos.

Para novos projectos, recomenda-se um pequeno ensaio com uma ou duas bobinas para verificar o desempenho antes do fornecimento em grande escala.

Conclusão

Corte de bobinas de aço é um processo aparentemente simples, mas tecnicamente exigente, que faz a ponte entre a produção de bobinas em bruto e o fabrico automatizado. Para OEMs e fabricantes, especificações claras, testes de validação antecipados e requisitos de qualidade de fornecedores específicos evitam dispendiosas interrupções a jusante. Quando incluídos em RFQs e acordos de qualidade, estes controlos de processo garantem que as tiras cortadas chegam prontas para alimentar as suas operações com rendimento e integridade de superfície previsíveis.

Sobre a Weijunli Steel

Para além da identidade de um fornecedor grossista de aço, A Weijunli Steel é uma empresa processador de aço também. A nossa fábrica está equipada com linhas de processamento dedicadas para o corte preciso de bobinas de aço. Estamos em condições de fornecer fornecimento grossista de aço e soluções personalizadas em aço com opções de serviços de processamento.

Cada fase segue procedimentos operacionais padronizados, alinhados com os requisitos internacionais de segurança e qualidade, garantindo um desempenho estável em todos os lotes. Com técnicos experientes a supervisionar a produção e a inspeção, mantemos especificações consistentes e uma entrega fiável.

Esta capacidade integrada permite Aço Weijunli para suportar diversas aplicações com precisão, tornando-nos um parceiro de processamento em que os clientes podem confiar.