最高級の冷延鋼板は、製品の品質、特定製品の製造歩留まり、総所有コストに直接影響します。ビジネスエンドのバイヤーやエンジニアにとって、典型的な最終用途と、板厚や公差、機械的特性、表面仕上げ、成形性などの重要なパラメータを一致させることが、最初に考慮すべきことです。.

今日、Weijunli Steelは、そのような 大手鉄鋼サプライヤーおよび加工業者, その一助となるべく、このブログを配信している。.

冷間圧延鋼の特性

冷間圧延鋼は、熱間圧延コイルを室温で還元することにより製造され、熱間圧延鋼に比べ、表面仕上げが改善され、寸法公差が厳しくなり、機械的一貫性が向上します。.

このプロセスには、目標とする延性と強度の範囲を達成するための焼鈍と調質圧延を含めることができる。.

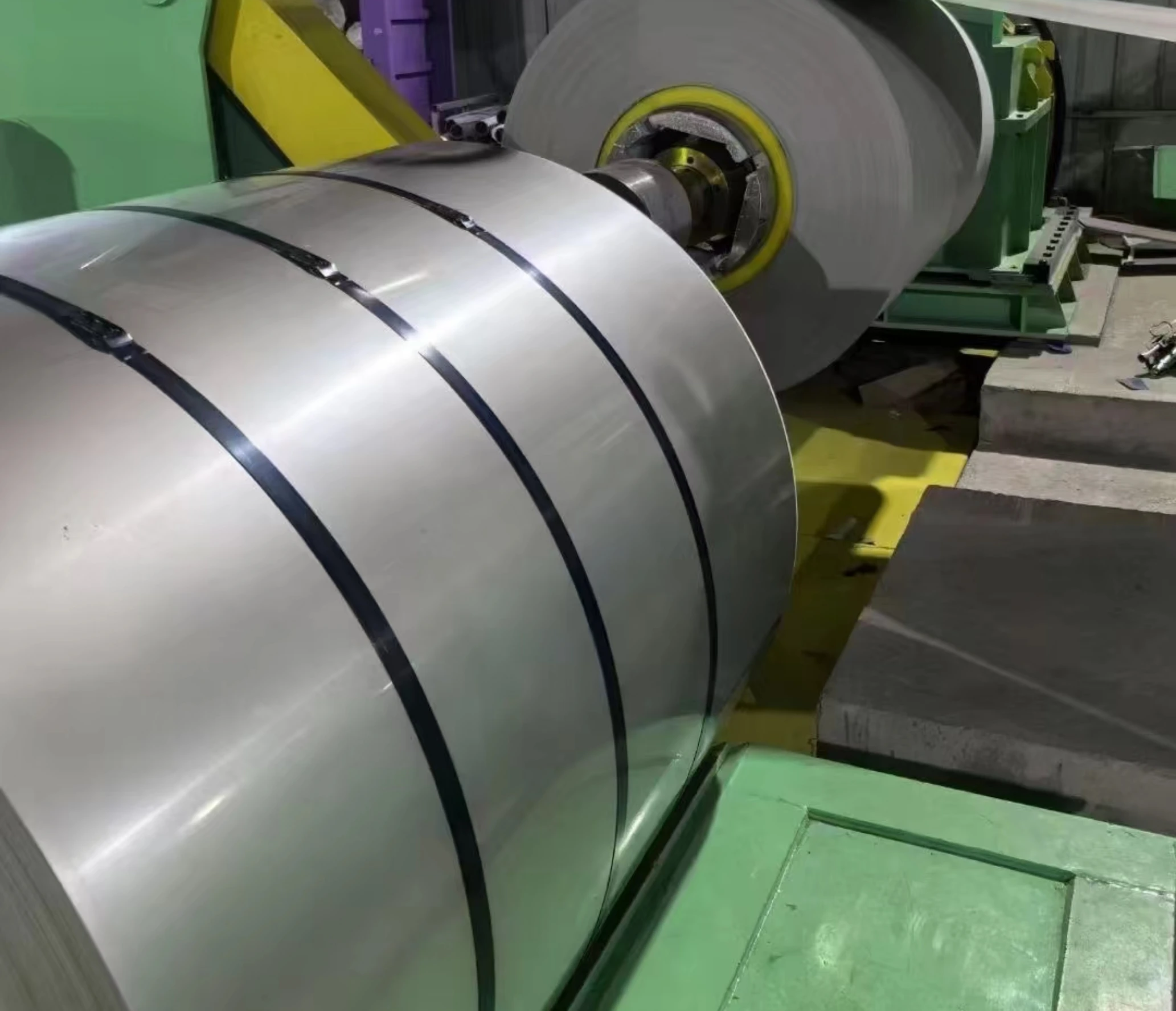

典型的な供給形態は、コイル、カット・ツー・レングス・シート、スリット・ストリップであり、それぞれが在庫、ハンドリング、下流工程に影響を与える。.

考慮すべき主要パラメータ

グレードを選択する前に、以下の4つの意思決定ドライバーに合わせる。.

厚さ、公差、平面度

厚みの許容差は、アセンブリのはめあいやスタンピングブランクのネスティングに影響します。はめあいが重要な場合は、絶対厚みと許容偏差(±0.03mmなど)を指定する。平坦度とコイルキャンバー許容差は、成形とプレス送りに影響します。精密部品には、より厳しい平坦度クラスが要求されます。.

機械的特性

成形荷重と使用荷重に基づいて、必要な引張強さ、降 伏強さ、伸びを決定する。一般的な冷間圧延材には以下のようなクラスがある:

- DQ/コマーシャル・クオリティ(CQ): 一般的な製造。.

- ドローイング・クオリティ(DQ): ディープ・ドローイングとディープ・ドロー・アプライアンス。.

- ディープ・ドローン・クオリティ/エクストラ・ディープ・ドローン・クオリティ(DDQ/EDQ): ひび割れを最小限に抑えた極端な成形。.

強度等級が高くなると、スプリングバックや金型の磨耗が増加することがあるため、強度と成形性のバランスを選ぶこと。.

表面品質と仕上げ

表面の種類は、明るくきれいなミル仕上げから、特殊な外観やメッキが可能な表面まで多岐にわたります。目に見えるパネルや塗装された製品には、粗さが少なく、欠陥のない表面が必要です。亜鉛メッキやメッキには、適合する表面処理(清浄度、油の種類)を選択する。.

成形性と加工適合性

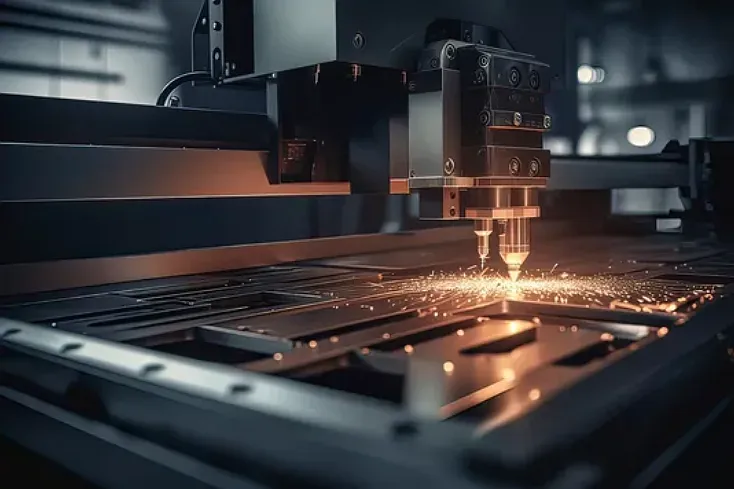

プレス、曲げ、ロール成形、レーザー切断、深絞りなどの主要な成形工程に材料を適合させます。材料の打ち抜き性、曲げ半径の性能、トリミングの挙動について、サプライヤーに問い合わせてください。.

最終用途で選ぶ

以下は、冷延鋼板を使用する際の一般的なB2B用途の推奨ガイダンス・ポイントである。.

家電パネルと精密鋳造品

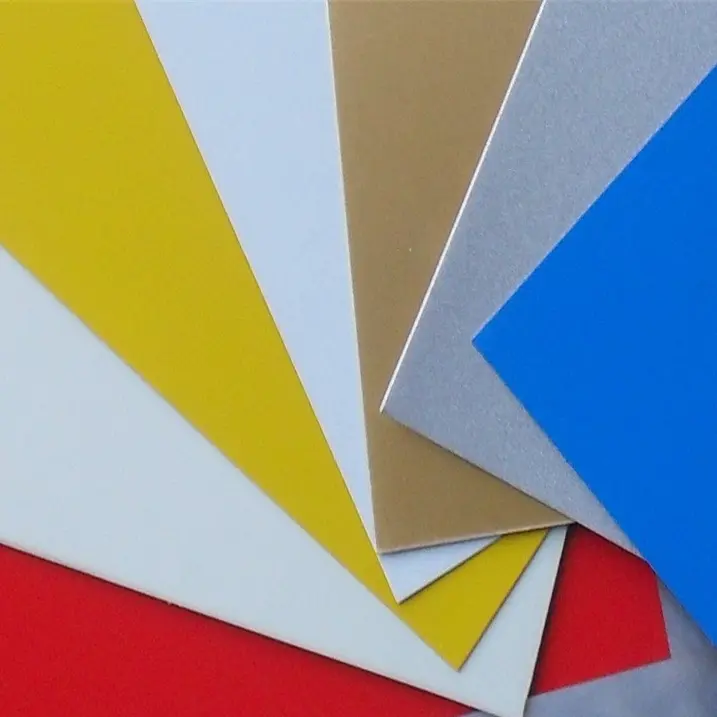

- 優先順位が高い: 表面仕上げ、深絞り性、カラーコーティング適合性。.

- 推薦する: DDQ / EDQ グレードの光沢表面(油引きまたは酸洗&油引き)。コイル塗装には調質圧延面を指定する。低含有率と優れた成形性が要求される。生産前のサンプルブランクと塗料の付着テストをご依頼ください。.

自動車内装部品および軽構造部品

- 優先順位が高い: 寸法管理、一貫した機械的特性、構造的特徴のための耐疲労性。.

- 推薦する: 成形の厳しさに適合した高品質のCR (冷延)鋼種-構造用ブラケットには高強度 のCRを使用するが、スプリングバックは 有効である。溶接と塗装の適合性のために、化学組成を厳密 に管理する。.

電気筐体および制御キャビネット

- 優先順位が高い: 平坦度、溶接性、塗膜密着性、耐食性。.

- 推薦する: 表面仕上げの良いCRシート(粉体塗装または塗装済み用途向け)。屋外で使用する場合は、冷間圧延下地に亜鉛メッキまたはプレガルバリウムコーティングを施してください。.

家具、ラッキング、棚システム

- 優先順位が高い: 費用対効果、成形性、自動化ラインでの一貫した厚み。.

- 推薦する: CQまたは商業用冷間圧延鋼種は標準表面仕上げ。化粧仕上げと腐食保護が必要な場合は、塗装済みCRコイルを選ぶ。.

精密部品、レーザー切断部品、CNC加工

- 優先順位が高い: 寸法精度、最小限のバリ形成、安定したエッジ品質。.

- 推薦する: 指定された厚さ公差と制御された硬さで冷間圧延され、機械加工性とレーザー切断パラメータをベンダーのサンプルで検証する。.

基準、成績、テストの点数

冷延鋼板を指定する場合は、公認の規格(ASTM、EN、JIS)を参照し、測定可能な許容基準を明記する:

- 化学組成 C、Mn、P、S)を制限し、溶接性と成形性を制御する。.

- 機械試験引張、降伏、伸び。.

- 表面検査許容可能な欠陥クラスと仕上げの指定。.

- 寸法試験複数のポイントでの厚み、平坦度、幅の許容差。.

- トレーサビリティ:ヒート/コイル番号が記載されたミルテスト証明書(MTC)。.

初注文の場合、サプライヤーにサンプルテスト報告書と出荷前写真を提出するよう要求する。.

表面処理と川下仕上げ

シートが必要かどうかを判断する オイル処理、酸洗&オイル処理、アニール処理、または塗装済み を冷間圧延鋼板に塗る:

- オイル漬け/ピクルス&オイル漬け: 保管中に保護するため、塗装前に洗浄する必要がある。.

- アニール処理(オックスフリー): 優れた成形性と安定した機械的特性.

- 塗装済み/塗装済み: コーティングシステム(PE、SMP、PVDF)と膜厚を指定します。.

選択した表面処理と、溶接、接着剤、コーティング工程との適合性を確認する。.

実践的調達チェックリスト

RFQとPOにこのチェックリストを使用する:

- 部品/用途の説明と成形プロセス。.

- 冷間圧延鋼板 グレードと標準リファレンス。.

- 厚さと公差の表。.

- 必要な機械的特性(引張/降伏/伸び)。.

- 表面仕上げと前処理仕様。.

- 試験および検査要件(MTC、接着、曲げ試験)。.

- 包装、ラベリング、輸送に関する指示.

- リードタイム、MOQ、および合意されたサンプリングプロトコル。.

結論

適切な冷延鋼板を選択するには、材料特性を製造の現実と最終用途の性能に合わせる必要があります。まず、その部品がどのように成形され、どのように仕上げられ、どのように使用されるかという機能要件を定義し、次にそれらのニーズを測定可能な材料仕様に変換します。適格なサプライヤーとの緊密な連携、初期段階でのサンプリング、明確な受入基準により、不測の事態を最小限に抑え、手戻りを減らし、製品ライフサイクル全体の総コストを最適化することができます。.

Weijunliスチールについて

Weijunliスチールは以下の事業を展開している。 大手鉄鋼サプライヤーおよび加工業者, を提供する。 卸売冷延鋼板 エンジニアリングと並行して供給 カスタム冷延鋼板ソリューション を多様な産業用途に提供しています。自社製造施設に支えられ、国際的に認知された安全基準と製造基準を遵守しながら、加工から納品までの品質を管理しています。この工場主導のアプローチにより、一貫した表面仕上げ、正確な公差、信頼できる供給性能が実現します。.

よくある質問冷間圧延鋼材を調達する際のバイヤーのよくある間違い

Q1: 冷延鋼板を注文する際、板厚と価格を指定するだけでよいのでしょうか?

A1: いいえ. .厚みや価格だけでは不十分です。バイヤーは、成形性、塗料の密着性、疲労性能などの機能要件も定義し、材料が意図する製造工程に適合することを確認する必要がある。.

Q2: バイヤーは大量注文の前に生産テストを行う必要がありますか?

A2:はい。. サンプルコイルでのスタンピング試験と塗装ベーク試験は、実際の生産性能を検証し、量産時の欠陥リスクを低減するのに役立ちます。.

Q3: なぜバッチ間の一貫性が重要なのですか?

A3: 一貫性のないバッチは、成形の不安定化や品質の問題につながる可能性がある。バイヤーは、サプライヤーの品質管理計画と最低限のバッチのトレーサビリティを要求すべきである。.

Q4: 梱包や取り扱いが鋼材の品質に影響することはありますか?

A4:はい。. 不適切な梱包は、輸送中にエッジの損傷、表面の傷、または錆を引き起こす可能性がある。保護的な梱包方法と明確な取り扱いSOPをあらかじめ定めておく必要がある。.