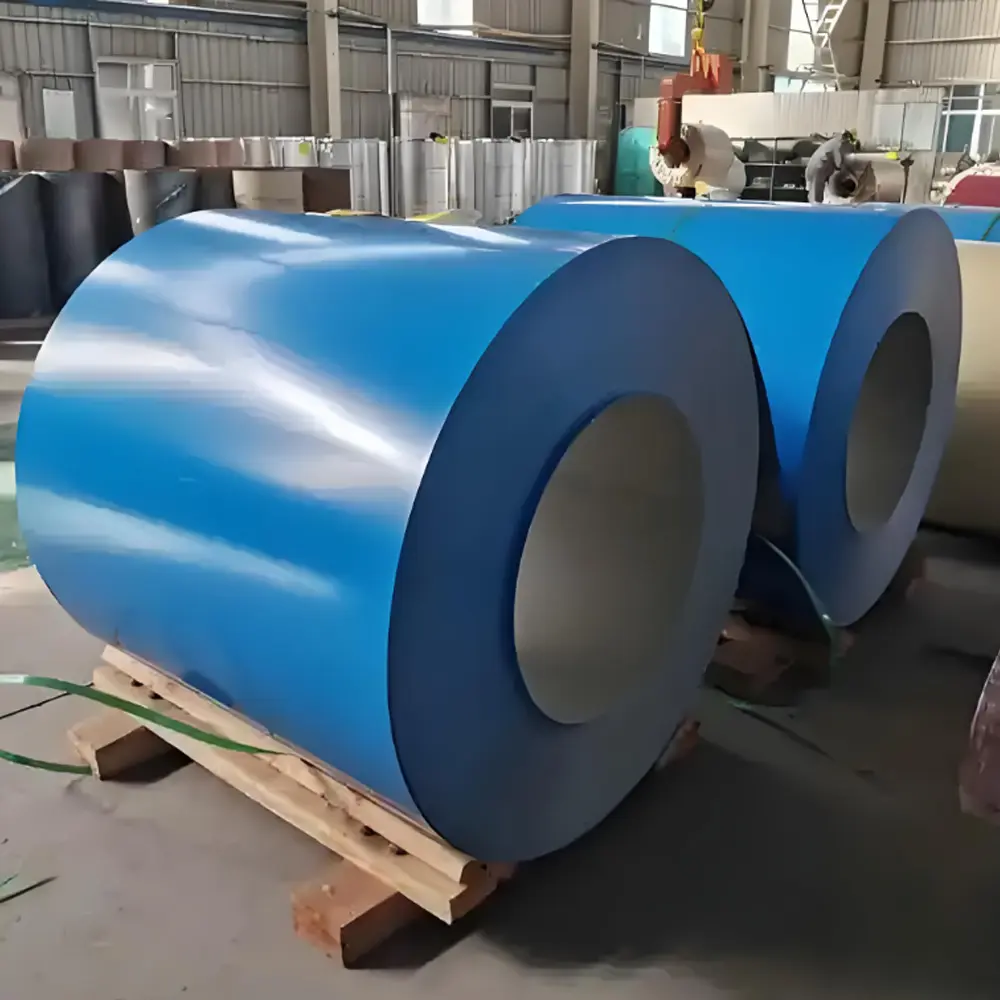

塗装済みスチール (PPGI/PPGLまたはプレコートメタルとも呼ばれる)は、加工前に工場のコイルコーティングラインで連続的に塗装された鋼材です。メーカーや設計者にとって、一貫した表面品質を実現し、製造工程を削減し、現場塗装や後塗装に比べてライフサイクルコストを改善することができます。.

このブログでは、Weijunli Steel, Inc. 大手鉄鋼サプライヤーおよび加工業者, また、B2B調達のためのバイヤーに焦点を当てた考慮事項も提供している。.

塗装済み鋼板とは何か、なぜ産業界はそれを使用するのか

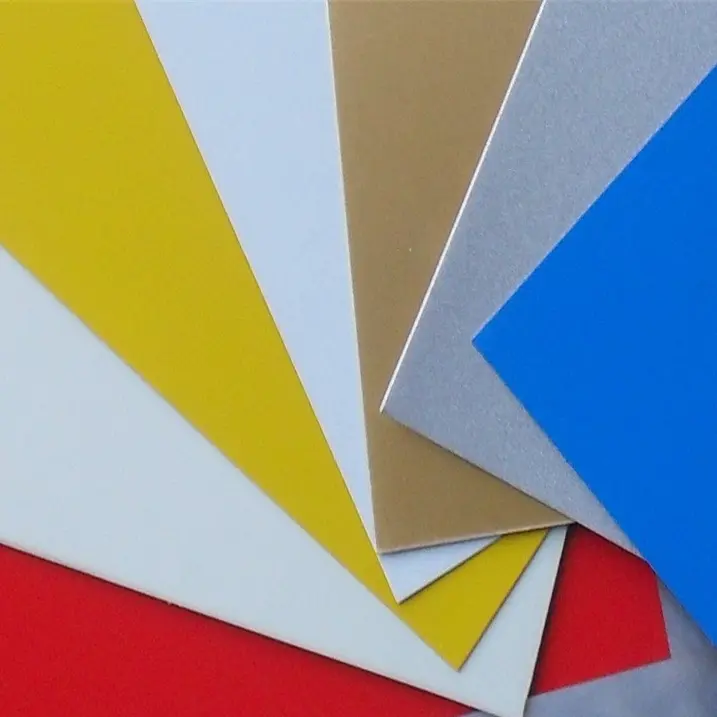

塗装済みスチール は、制御された塗装システム(下塗り+上塗り)を連続ラインで鋼鉄基材に塗布し、通常、その後、硬化と検査を行うことで製造される。このプロセスは後塗装鋼板とは異なり、下流のスプレー塗装ではなく、厳しく管理された条件下で工場で塗装される。.

OEMやメーカーにとって、そのメリットは単純明快だ:

- 安定した均一な表面品質 色、光沢、膜厚が安定している)。.

- 生産サイクルの短縮 また、工場内の塗装ラインを削減し、スループットの向上を実現した。.

- 製造コストの低減 労働力の削減、手戻りの減少、VOC/許可証の負担の軽減を考慮した場合。.

というのも、コーティングは工場出荷時の状態で施されるからだ、, 塗装済み鋼板 は、外観、耐久性、プロセスの信頼性が優先される場合、しばしば第一選択の基板となる。.

主なパフォーマンス特性

業界のアプリケーションを検討する前に、以下のような技術的特性を理解することが役立つ。 塗装済み鋼板 魅力的だ。.

- 耐食性 - 下地(亜鉛メッキ、ガルバリウム)と塗膜の化学的性質の選択により、期待される耐用年数が決まります。.

- 色の一貫性とデザインの柔軟性 - コイルコーティングは、精密なカラーマッチングとスケールでのパターン印刷をサポートする。.

- コーティングの密着性と成形性 - コイルコーティングシステムは、曲げ、スタンピング、ロール成形に耐え、ひび割れを最小限に抑えるように設計されています。.

- 生産効率と廃棄物削減 - 塗装済みコイルは、現場での塗装を減らし、オーバースプレーの廃棄物や再作業を削減します。.

このような性能特性は、なぜ複数の産業部門が以下の製品を標準としているのかを説明するものである。 塗装済み鋼板 大量生産向け。.

建設分野での応用

屋根・壁パネル

の最大の最終市場のひとつである。 塗装済み鋼板 波板屋根、スタンディングシーム屋根、断熱パネルなどである。その主な理由は、長期間の色調保持、耐候性、一貫した仕上がりで連続した長さを大量に供給できることである。適切な下地(ガルバリウムなど)と組み合わせることで、塗装済み製品は最小限のメンテナンスで数十年の耐用年数を実現します。.

内装クラッドおよび装飾パネル

塗装済みコイルは、内装建築パネルやモジュール式壁面システムにも最適です。設計者は数百平方メートルにわたって均一な外観を重視し、建物の所有者は汚れや磨耗に強い低メンテナンスの表面から利益を得ます。.

建設業に有効な理由

設計された基材、工場で塗布されたコーティング、コイル成形の効率の組み合わせにより、以下のことが可能になります。 塗装済み鋼板 は、仕上がりの一貫性、リードタイム、ライフサイクルの総コストが重要な大規模プロジェクトに適した論理的な選択肢です。.

家電製品への応用

家電製品のケーシングと外装パネル

大手家電メーカーが採用 塗装済み鋼板 冷蔵庫の扉、洗濯機の浴槽、ホブのパネル、エアコンのキャビネットなどに使用されています。コイル・コーティングは、生産工程全体にわたって色と光沢を保証し、組立ラインでの塗装を削減します。.

内部構造部品

バックパネル、取り付けブラケット、インナーライニングは、耐食性を向上させ、二次加工を減らすために、塗装済みで提供されることが多い。.

家電OEMが塗装済み鋼板を好む理由

これを使用することで、社内の塗装ブースが不要になり、VOC排出量が削減され、ファーストパスの歩留まりが向上し、ラインから出荷されるすべてのユニットが同じ仕上げ品質であることが保証される。.

パッケージングへの応用

工業用および設備用包装

塗装済みスチールは、印刷されたブランディングと耐久性のある表面が必要な金属製エンクロージャー、輸送用クレート、保護ハウジングに使用されます。.

印刷マーキング付き塗装済みスチール

塗装済みコイルへのミル塗布印刷は、ロゴ、安全マーキング、説明用グラフィックに一般的です。この方法は、二次的なラベリングに取って代わり、インクの粘着性と耐久性を確保しながらトレーサビリティを向上させます。.

なぜパッケージに合うのか

高い再現性、耐摩耗性、コイル段階での印刷情報の組み込みが可能である。 塗装済み鋼板 標準化されたパッケージとブランド名入りの筐体を効率的に使用できる。.

塗装済み鋼鉄と塗装後鋼鉄の比較 - 工業製品比較

| 基準 | 塗装済みスチール | ポスト塗装スチール |

|---|---|---|

| 表面の一貫性 | 高(工場制御) | 可変(ショッププロセス) |

| 生産の流れ | より速く(塗装ラインなし) | 遅い(塗装工程が必要) |

| VOC/環境 | 低い(集中管理) | 高い(店舗排出ガス) |

| 規模に応じたコスト | 大量生産でTCOを削減 | CAPEXは低いがOPEXは高い |

| 修理可能性 | タッチアップが可能。 | 現地での修理は容易だが、仕上がりはまちまち |

B2Bの大量生産向け、, 塗装済み鋼板 通常、総コストは削減され、後塗装に比べて品質管理が向上する。.

B2Bバイヤーの主な検討事項

を指定する場合 塗装済み鋼板, 調達チームが取り組むべきこと

- ベーススチールの選択: GI(亜鉛メッキ)、GL(ガルバリウム)、CR(冷間圧延)、HR(熱間圧延)があり、腐食や成形性のニーズに応じて選択できる。.

- コーティングシステムの選択: PE、SMP、PVDF - 耐久性、色持ち、保証の期待に基づいて選択する。.

- カラーマッチングとバッチの一貫性: M標準、スペクトルマッチ、バッチサンプルをリクエストする。.

- MOQ、リードタイム&QC: 特注色/柄の最低注文数量を理解し、出荷前検査、接着、塩水噴霧試験報告書を要求する。.

紛争を避けるため、明確な受入基準(膜厚、接着性、成形性試験)を発注書に盛り込む。.

業界標準と品質管理

関連規格(ASTM、EN、ISO)は、下地処理、塗膜厚さ、付着性試験、耐食性を対象としている。塗装済み鋼板の代表的な試験には、クロスカット付着性、マンドレル曲げ/成形試験、塩水噴霧、QUV耐候性などがあります。長期保証を求めるOEMには、サプライヤーの試験証明書と製造工程の監査が必要です。.

結論

建築、電化製品、産業用パッケージングにおいて、塗装済み鋼板は、一貫した外観、工程の複雑さの軽減、ライフサイクルコストの削減を実現する実証済みの方法を提供します。工程管理、環境管理、色の一貫性が最大化される塗装工程を工場に移すことで、メーカーはより優れた品質を大規模に実現することができます。.

Weijunliスチールについて

Weijunliスチールは 大手鉄鋼サプライヤーおよび加工業者, に焦点を当てた。 卸売塗装鋼材の供給 そして カスタム塗装済みスチールソリューション 産業用および建設用。.

工場直送のパートナーとして、当社は国際的に認知された安全基準と生産基準の下で操業し、安定した品質と一貫した生産量を確保しています。当社の加工能力により、仕様、コーティング、および仕上げを実用的なプロジェクト要件に合わせることができ、長期供給のための信頼できる選択肢となります。.