You probably see galvalume steel every day — on rooftops, garage doors, and appliance backs. Its silvery finish keeps buildings cooler and resists rust, quietly protecting structures and products for decades.

As a leading steel supplier and processor from China, Weijunli Steel is going to show you more applications of galvalume steel and why it is chosen.

Quick Glance at Galvalume Steel

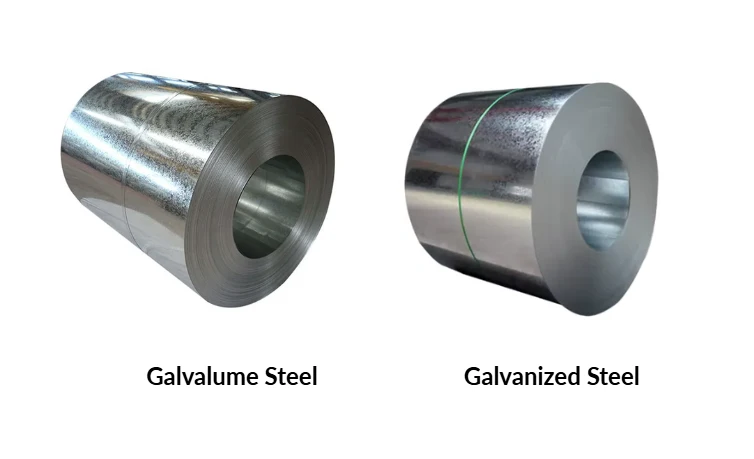

Galvalume steel refers to sheet, strip, or coil coated by a hot-dip process with an aluminum-zinc alloy (nominal 55% Al / 43.4% Zn / 1.6% Si). This Al–Zn coating pairs aluminum’s long-term barrier protection with zinc’s local sacrificial protection, producing a durable, reflective, and thermally stable surface.

Those properties explain why galvalume steel is widely selected across roofing, cladding, appliances, automotive components, and industrial uses.

Core Applications of Galvalume Steel

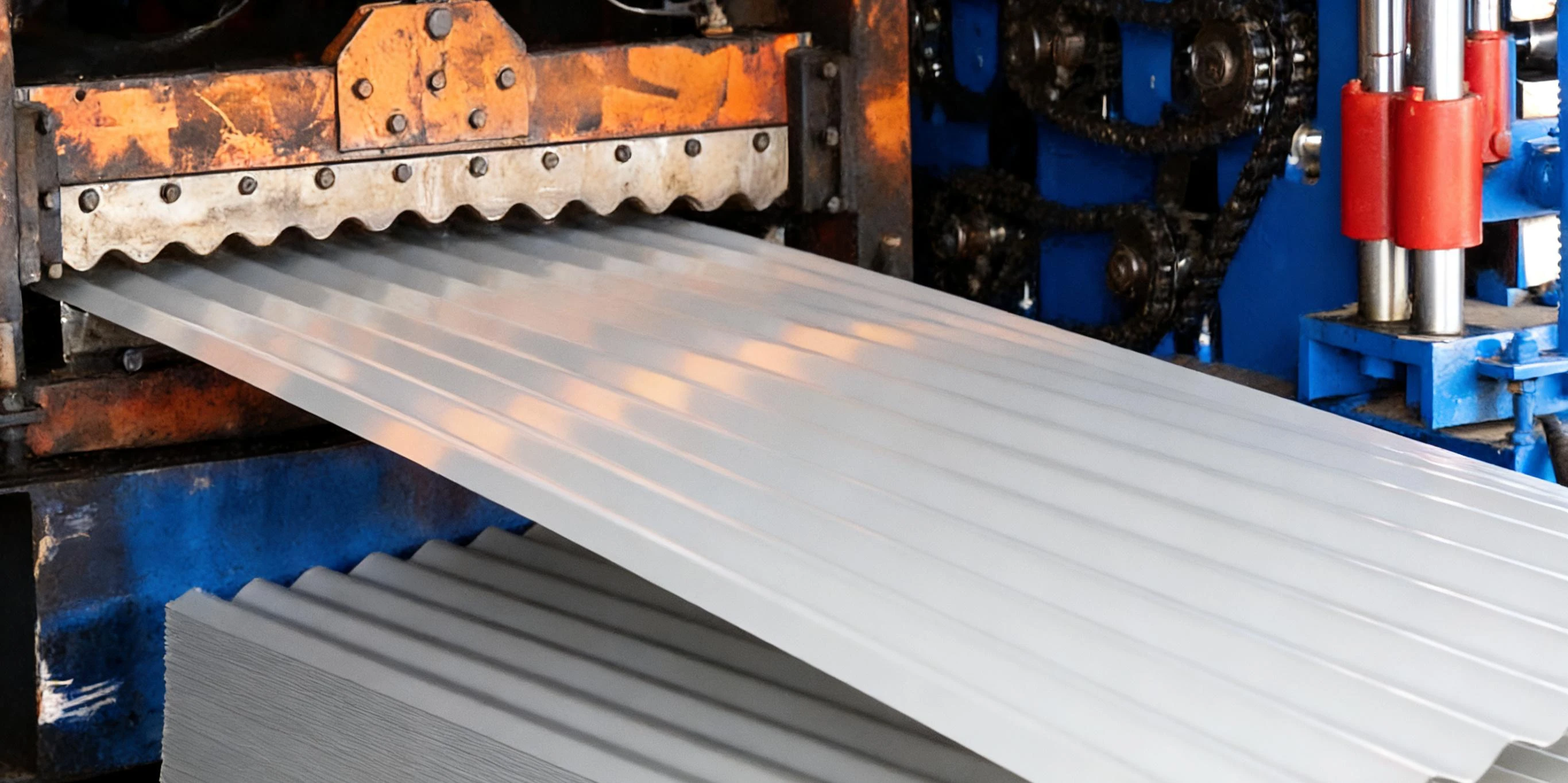

1. Roofing & wall panels (largest application)

Galvalume steel is the dominant choice for corrugated roofing, standing seam panels, and metal cladding. Its superior performance under wet/dry cycles, longer service life versus galvanized systems, and high solar reflectance reduce roof temperatures and building energy demand. Typical uses include warehouses, factories, commercial roofs, and residential carports.

2. Residential building components

Gutters, downpipes, light-steel framing, and carport roofs commonly use galvalume steel. The material’s corrosion resistance, combined with its suitability for coil coating, provides durable, attractive finishes for homes and small buildings.

3. Commercial & industrial facades

Cold stores, distribution centers, airport hangars, and industrial facades benefit from galvalume steel’s resistance to acid rain and humid environments. Long service life and low maintenance make it ideal for large exterior envelopes.

4. Appliances & HVAC components

Internal chassis, back panels, and ductwork in refrigeration and HVAC systems use galvalume because it handles humid, condensating conditions better than simple zinc coatings and provides a stable substrate for painted finishes.

5. Automotive & high-temperature components

Non-decorative, heat-exposed parts (e.g., certain heat shields, exhaust system panels) can use galvalume because its Al-rich coating resists high-temperature oxidation better than pure zinc.

6. Agricultural & outdoor structures

Silos, barns, fencing, greenhouse frames, and rural outbuildings often use galvalume for its long outdoor life and cost advantage over stainless steel.

7. Solar racking & infrastructure

Galvalume’s reflectivity and corrosion resistance make it a practical choice for photovoltaic racking systems and outdoor structural parts in renewable energy installations.

Why Designers and Specifiers Choose Galvalume Steel

The decision to specify galvalume steel is driven by several material properties that directly map to application needs:

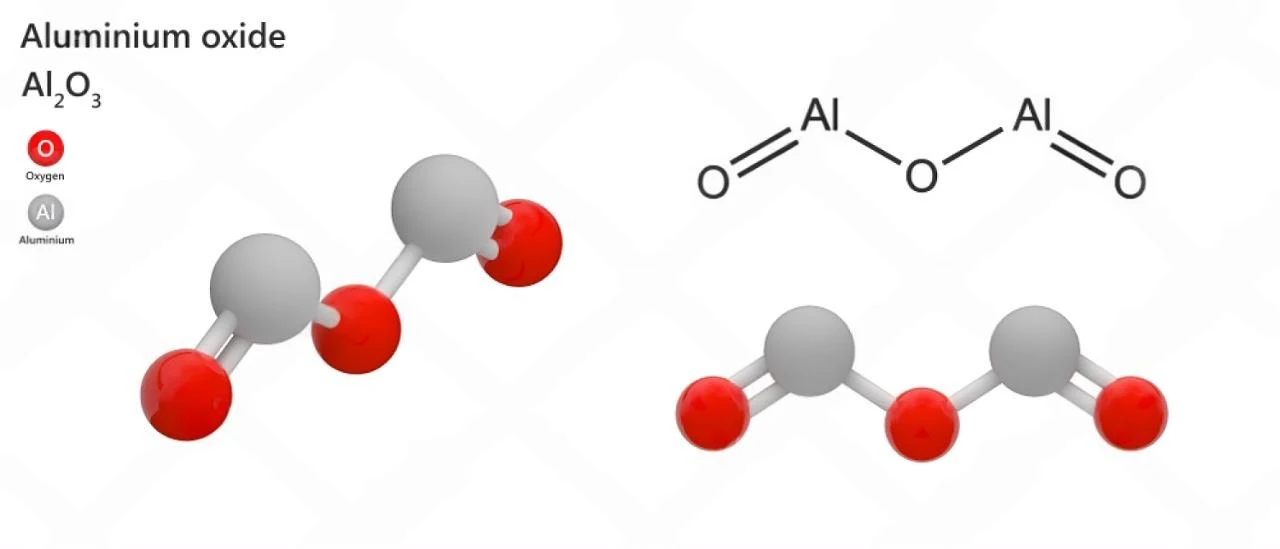

Barrier protection from aluminum

The aluminum component forms a compact aluminum-oxide film (Al₂O₃) on the coating surface. This barrier significantly slows oxygen and moisture ingress, improving long-term corrosion resistance — vital for roofs and exposed cladding.

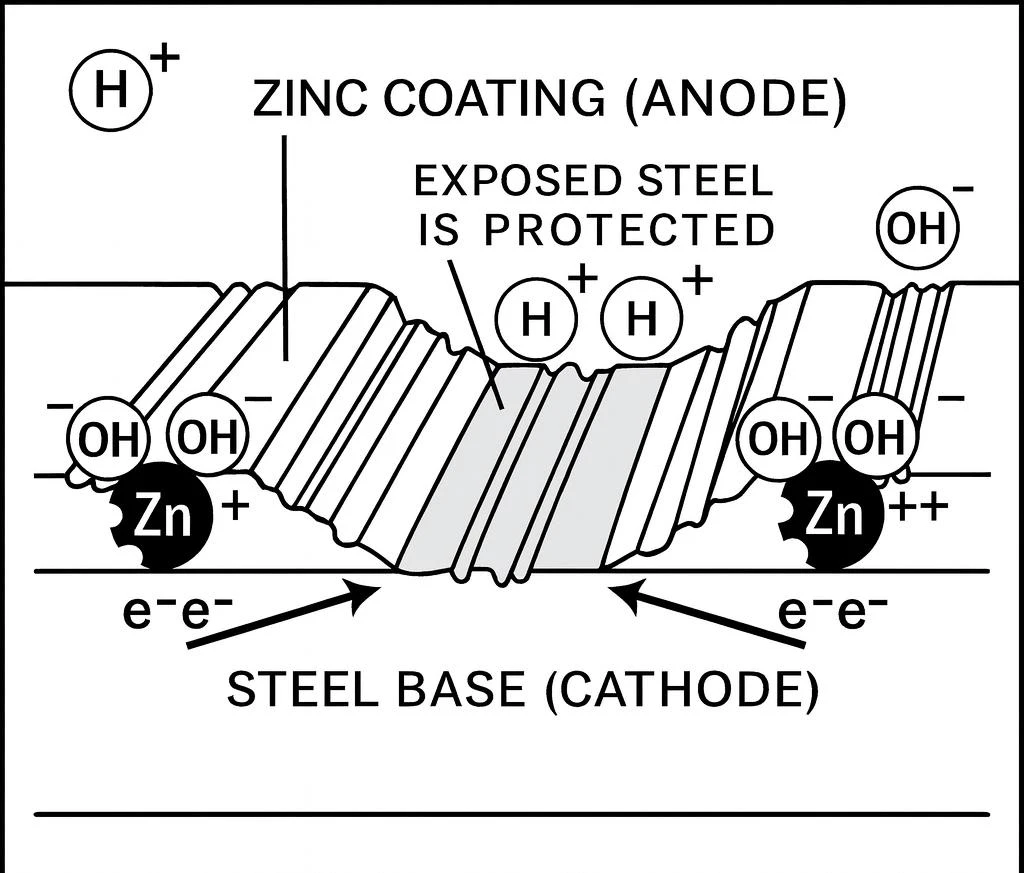

Local sacrificial protection from zinc

Where the coating is scratched or cut, embedded zinc provides local cathodic protection, slowing corrosion progression at edges and fastener holes. This “self-healing” behavior is important for fabricated panels and on-site handling of damage.

Superior high-temperature stability

Aluminum in the coating increases resistance to oxidation and powdering at elevated temperatures (useful up to ~300–400°C in many cases), enabling galvalume steel use in heat-exposed applications like high heat exhaust, where galvanized coatings would fail.

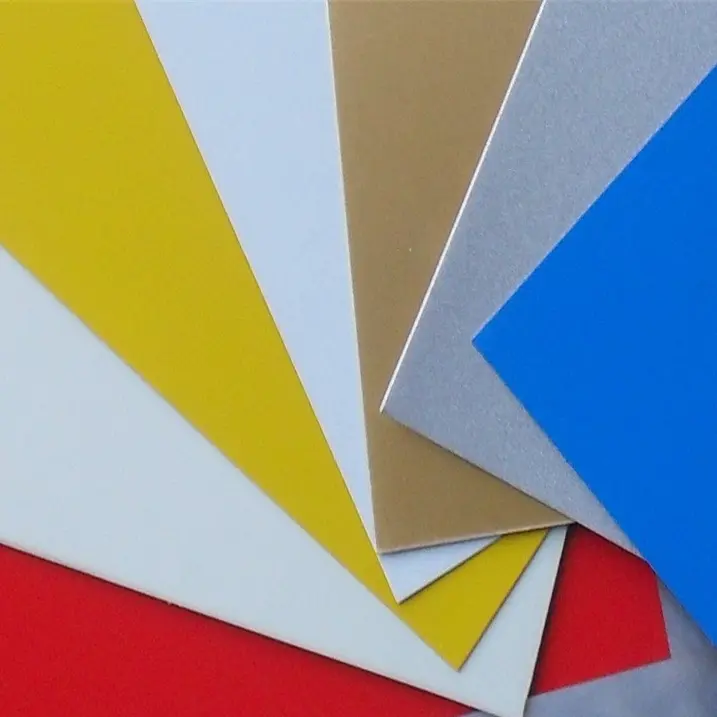

Better surface for coating and aesthetics

Galvalume’s smoother, uniform finish accepts coil coatings and paints more evenly than spangled galvanized surfaces, producing high-quality architectural finishes and colored façades.

Formability and fabrication compatibility

Galvalume remains readily formable for roll-forming, bending, and light stamping and can be welded with standard practices (with appropriate fume controls). This supports its use in complex building components and appliance parts.

Lifecycle cost advantage

Compared with stainless steels, galvalume often achieves the required service life at a significantly lower material cost. Compared with galvanized steel, galvalume generally delivers longer service life and lower maintenance in many atmospheres, reducing total lifecycle cost.

Practical Selection Guidance

Specify Coating Mass (AZ Rating): Specify Coating Mass using AZ numbers for both sides of the substrate in grams per square metre (example AZ50 or AZ150) to specify the environment and the expected length of service life.

Environmental Assessment: For chemically aggressive environments or offshore applications, consider a duplex system (Galvalume + High Performance Exterior Coating) or an alternative alloy system.

Protection for Edges and Fasteners: Use compatible fasteners, isolation washers, and repair (touch-up) products for protection at cut edges and at drilled holes.

Compatibility with Coil Coated Systems: For all paint systems, specify the pretreatment and paint system (Example: PVDF) to assure adhesion and to assure the manufacturer will cover warranty coverage.

Conclusion

Galvalume steel combines aluminum’s barrier protection and zinc’s sacrificial behavior into a cost-effective, durable coating that suits a very wide range of outdoor, high-temperature, and painted applications. Its mix of corrosion resistance, reflectivity, formability, and economic value explains its dominance in roofing, cladding, appliances, and more.

When specifying coated steel, prioritize AZ coating mass, environmental exposure, edge protection, and installation detailing to fully realize galvalume’s longevity and performance.

Weijunli Steel – Your Reliable Galvalume Steel Supplier

Weijunli Steel stands as a leading steel supplier, focused on delivering stable, high-quality wholesale galvalume steel supply to global partners. Backed by our own production facility, every batch is processed under internationally aligned SOP systems, ensuring consistency, durability, and traceable quality.

We provide a broad portfolio of steel formats—including coil, strip, plate, and sheet—allowing buyers to source precisely what their projects require. For brands seeking differentiation, our custom galvalume steel solution offers tailored specifications in coating, width, thickness, and surface treatment.