Selecting the correct steel coil upstream has a direct, measurable impact on the quality, yield, and runnability of the steel strip you feed into downstream processes. A poor coil choice can produce excessive burrs, camber, inconsistent slit widths, and unexpected scrap — all of which raise cost and disrupt production.

In this guide, Weijunli-Stahl, a führender Stahllieferant, will walk procurement and engineering teams through the technical and commercial criteria that matter when buying coils intended for slitting into strips

Understand the Slitting Process First

Slitting is a longitudinal cut: a wide parent coil is split into multiple narrower strips by rotary knives and then recoiled. Unlike transverse cut-to-length, slitting imposes unique stresses on the material (knife contact, localized shear, differential tension among strips). Some coils tolerate those stresses better than others; choosing the wrong coil magnifies edge defects, camber, and burr formation.

Base Steel Type: Match Material to Application

Different substrates behave differently during the slitting process into the steel strip, and in the end are used:

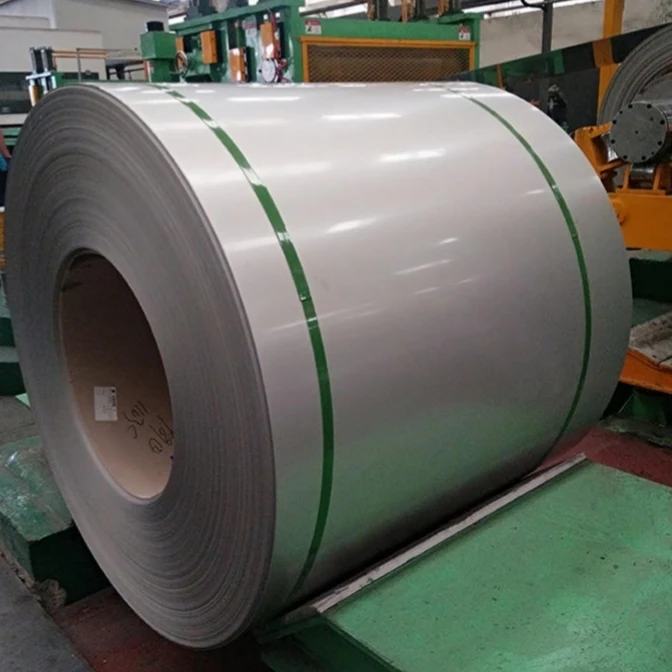

- Cold-rolled steel (CR): Best surface finish and tightest tolerances. Preferred for precision steel strip used in stamping, appliance panels, and prepainted applications.

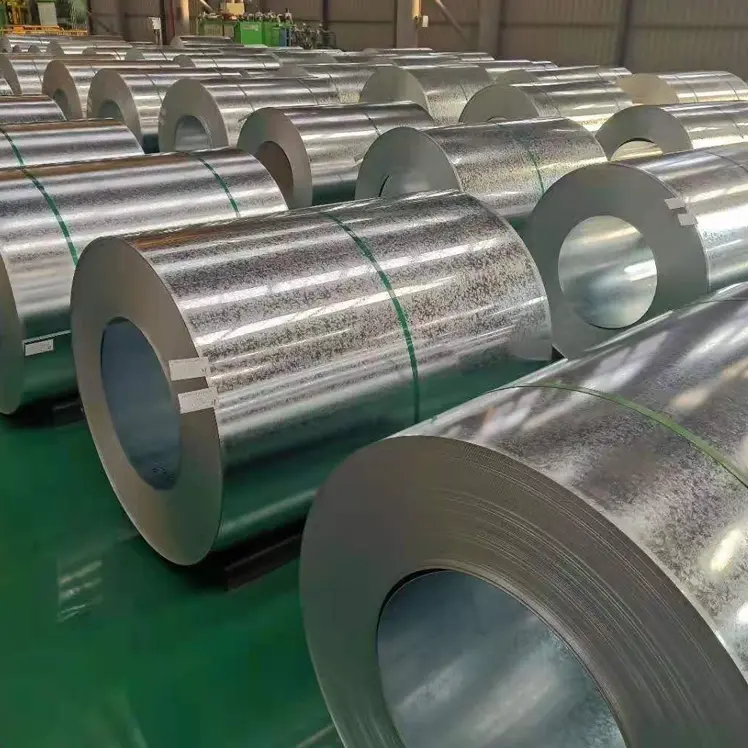

- Galvanized (GI): Adds corrosion protection but requires attention to coating weight and edge behavior (zinc can smear) and monitoring “Zinc Build-up” on knives to prevent gap deviations during long runs. Useful when rust protection is needed without painting.

- Galvalume / Al–Zn coated (GL): Offers superior corrosion resistance and heat reflectivity; slitting needs careful control because coating brittleness can affect edge quality and lead to micro-cracking at the shear zone.

- Hot-rolled pickled & oiled (HRPO): Cost-effective for heavier-duty strips but carries wider thickness tolerance and more residual stress.

Choose the base type based on the downstream requirement: cosmetic panels demand CR; structural or protective strips may use GI/GL or HRPO.

Thickness, Width, and Tolerance Planning

Precision in thickness and width is non-negotiable for many production lines:

- Thickness consistency across the coil reduces springback variation and helps maintain edge form after slitting. Specify the maximum across-coil variation you can accept (e.g., ±0.02 mm).

- Parent coil width vs. final strip widths: Plan the nesting so trim loss is minimized. The parent width must allow an optimal layout of strips without excessive leftover trim.

- Tolerance stacking: Consider how coil tolerance, slitting tolerance, and downstream forming tolerances add up. Request clear tolerances for the parent coil and target strip.

Minimum practical slit width depends on equipment and material; verify with your slitter supplier before ordering coils.

Mechanical Properties and Slitting Performance

Material strength, ductility, and hardness influence edge quality and tool wear:

- Yield & tensile strength: Higher strength increases cutting force and blade wear; very high-strength coils may require special knife materials or slower speeds.

- Elongation: Low elongation can cause edge cracks during bending or forming; for deep drawing or roll-forming strips, choose higher-ductility grades.

- Hardness: Harder materials increase blade wear and may produce raised burrs; plan maintenance intervals accordingly.

Match the coil’s mechanical profile to the intended forming process to avoid surprises.

Surface Condition and Coated Materials

Surface state affects slitting behavior and final steel strip appearance:

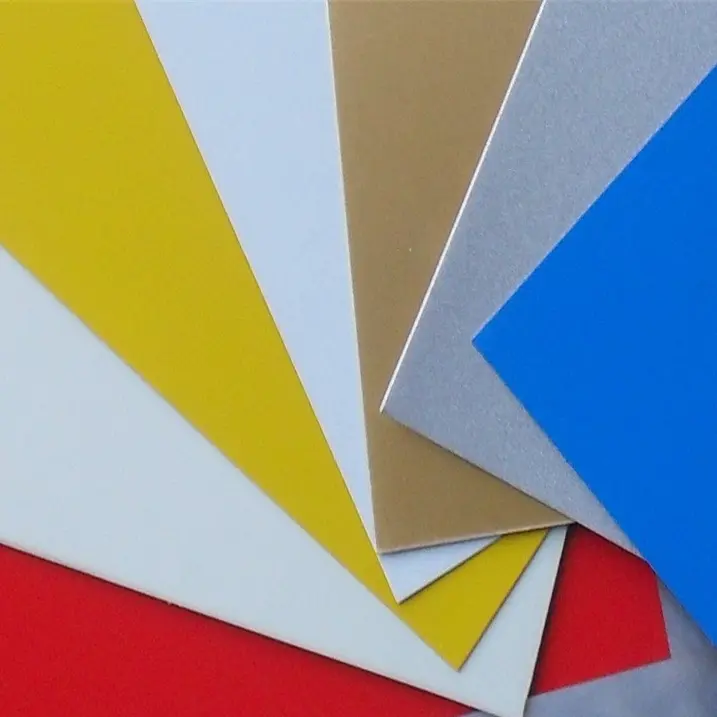

- Surface finish: Bright / skin-passed / matte finishes have different lubrication and abrasion characteristics. Decorative applications require cleaner surfaces with minimal defects.

- Coating weight & uniformity (GI/GL): Non-uniform coatings cause inconsistent shear during slitting and variable edge appearance. Always request coating mass (g/m²) data.

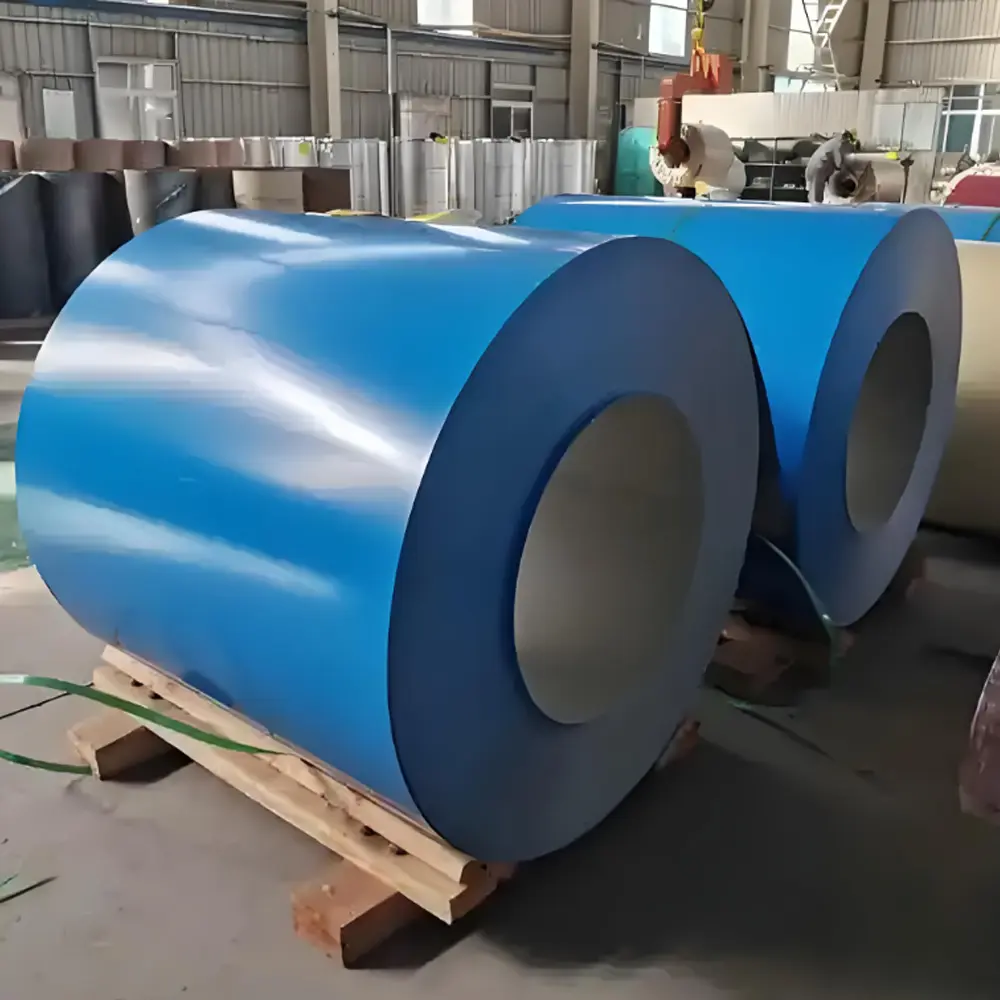

- Prepainted or preprinted coils: If you slit pre-coated material, protective film, wrap, and tooling are essential to prevent scratching and edge chipping.

Specify whether you require protective film, interleaving, or special cleaning before slitting.

Coil Geometry and Handling

Coil dimensions and geometry must match both the slitting equipment and your downstream line:

- Inner diameter (ID) and outer diameter (OD): They affect uncoiler fit and mandrel engagement. Mismatches can cause telescoping or runout.

- Coil weight: Ensure your recoiler/uncoiler and handling equipment can manage the coil mass safely.

- Camber and coil set: Excessive camber leads to strip wander; inspect parent coils for camber limits acceptable to your process.

Confirm coil specs in the PO and have suppliers pre-check coil geometry before shipment.

Edge Quality Expectations After Slitting

Be explicit about acceptable edge conditions:

- Burr height: Define maximum allowable burr as <10% of material thickness (e.g., <0.1 mm for 1mm strip).

- Edge rollover and fracture: Some forming operations are sensitive to rollover. State application-specific edge requirements in procurement documents.

- Trim loss planning: Ask suppliers to present estimated trim scrap per coil layout.

Clear edge specifications reduce rework and help suppliers set blade gaps and speeds appropriately.

End-use Driven Coil Selection

Let the intended use drive coil choice:

- Stamping / deep drawing: Prioritize DDQ/EDQ cold-rolled coils with high formability and low inclusion content.

- Roll forming/profiles: Stable thickness and low camber are key; mid-strength cold-rolled or HRPO may suffice depending on load.

- Welded parts / tubulars: Consider coil cleanliness and edge metallurgy for reliable welds.

Work with engineering to map end-use requirements to coil attributes before RFQ.

Supplier Capability, QC, and Documentation

A technically capable supplier reduces risk:

- Mill source consistency: Prefer suppliers who can commit to consistent mill batches or traceable heats.

- Slitting experience & tooling: Verify their blade materials, knife-change procedures, and maintenance cadence.

- SPC and traceability: Require sample SPC charts, first-coil reports, and heat/coil IDs with every delivery.

- Testing: Request MTCs, coating mass reports, and pre-shipment photos for first orders.

These controls ensure that the steel strip arriving at your line behaves predictably.

Cost, Yield, and Commercial Trade-offs

Balance price per ton with usable output:

- Trim scrap reduces usable yield; negotiate pricing with realistic net yield assumptions.

- MOQ and scheduling: Small custom widths increase setup cost; group similar sizes to reduce cost.

- Total cost of ownership: Cheaper coils that cause downtime or rework are rarely economical.

Ask suppliers for yield simulations and total-cost comparisons for candidate coil options.

Schlussfolgerung

Choosing the right coil for slitting is a multidisciplinary decision that combines material science, equipment compatibility, and commercial planning. Start with the end use, define measurable acceptance criteria (thickness, edge, camber), and work with suppliers who provide traceable documentation and demonstrated slitting experience. Doing so transforms steel strip procurement from a price exercise into a predictable supply strategy that protects production uptime and reduces total cost.

Über Weijunli Steel

Weijunli Steel is a führender Stahllieferant und -verarbeiter, focused on offering wholesale steel coil, steel strip, steel sheet, and steel plate supply and delivering Maßgeschneiderte Stahllösungen for industrial and construction applications.

As a factory-direct wholesale steel strip partner, we operate under internationally recognized safety and production standards to ensure stable quality and consistent output. Our processing capabilities allow specifications, coatings, and finishes to be tailored to practical project requirements, making us a reliable choice for long-term supply.