Small stamped hardware parts — door handles, clips, hinges, and small brackets — look simple, but they amplify any imperfection in the steel quality. For procurement teams and manufacturing engineers, Weijunli-Stahl knows that amplification is the reason a seemingly minor supplier choice becomes a recurring production headache.

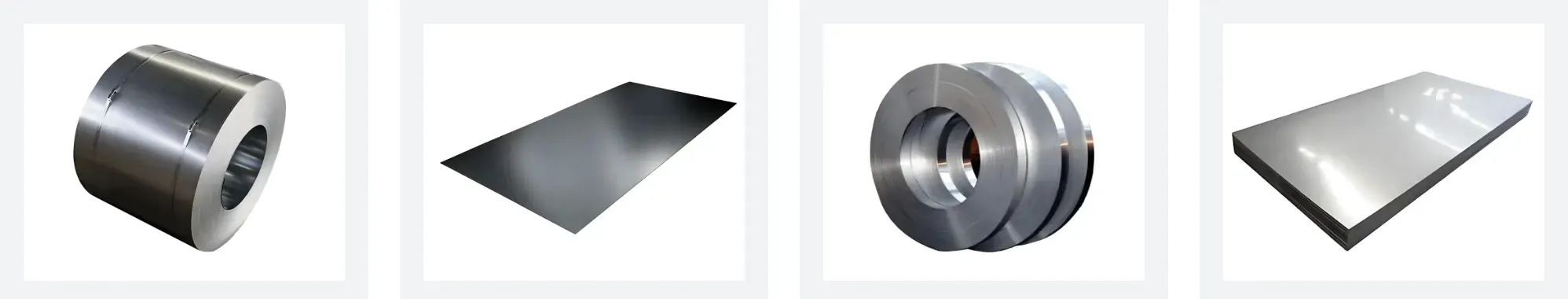

Als ein führendes steel coil supplier and processor, We are delighted to explain the mechanisms behind that sensitivity, translate the implications for B2B buyers, and give concrete specifications and supplier-evaluation advice you can use immediately.

How Stamped Part Size Magnifies Material Issues

Three physical realities make small parts much less forgiving than large panels or structural members:

- Narrower tolerance windows. A small clip has a much smaller dimensional window before it fails to assemble or function. Minor thickness variation or local paint build-up that larger parts absorb will push small parts out of tolerance.

- Concentrated deformation. Small components often form at concentrated local strains. Where a large panel can redistribute deformation over a broad area, a small stamped geometry focuses strain into a tiny region — and that is where a marginal material will crack.

- One-shot processes. Many small parts are formed in a single stamping operation; there is no multi-stage recovery or rework. If the sheet material exhibits a hard spot, unexpected yield, or slightly different elongation, the defect goes straight into the finished part.

All these three translate to higher scrap risk, more tooling downtime, and greater variability in first-pass yield — a direct hit to margins and on-time delivery.

What “Steel Quality” Means for Small Hardware

When buyers say “improve steel quality,” they usually mean one or more practical attributes that affect forming and finishing performance:

- Thickness consistency across the coil (minimizing gauge variation)

- Surface condition (low Ra, cleanliness, no embedded debris)

- Mechanical consistency (stable yield strength and elongation from coil to coil)

- Edge condition after slitting (burr height and edge rollover)

- Batch traceability (heat/coil IDs, MTC) so you can correlate problems to material lots

For small hardware, these are not academic metrics — they are the difference between a 98% and an 80% first-pass yield.

Common Steel Types Used in the Hardware Industry — and Their Real Impacts

| Steel Type | Typical Use in Hardware | Real impact on small stamped parts |

|---|---|---|

| Cold-rolled steel (CRS) — e.g., SPCC / DC01 | Precision-stamped parts, decorative hardware | Tight tolerance and smooth surface enable stable forming, low crack risk, and consistent plating. |

| Galvanized steel (GI) | Outdoor hardware, corrosion-protected parts | Zinc coating improves corrosion resistance but can affect edge quality and forming consistency. |

| Galvalume / Al-Zn coated steel (GL) | Roofing components, some painted hardware | Strong corrosion resistance; coating requires controlled slitting and forming for small parts. |

| Hot-rolled steel (HR / HRPO) | Heavy brackets, non-cosmetic structural parts | Lower surface quality and dimensional accuracy limit use in precision or decorative parts. |

| Stainless steel (e.g., 304, 316) | High-corrosion or aesthetic applications | Excellent durability, but higher forming difficulty and faster die wear. |

| Aluminum / Zinc alloys | Decorative or lightweight parts | Lightweight options that require different tooling and finishing processes. |

Typical Failure Modes for Small Parts and Their Root Steel Material Causes

- Cracking at bends or cutouts → often caused by local low elongation or high hardness in the coil.

- Poor plating adhesion or “mottled” finish → linked to surface contamination, inconsistent Ra, or incompatible coating metallurgy.

- Excessive burrs or edge fractures after slitting → due to improper knife settings interacting with harder-than-expected material.

- Dimensional drift between batches → coil-to-coil thickness/flatness variation or inconsistent temper rolling.

Each failure mode has a procedural fix — but the most cost-effective mitigation is specifying the right steel quality and enforcing supplier controls up front.

What Buyers Must Specify About Steel Quality

To reduce downstream risk, RFQs should contain measurable, actionable requirements:

- Material grade and standard (e.g., SPCC / DC01 for cold-rolled bright coil).

- Thickness tolerance and maximum across-coil variation (e.g., 0.8 mm ±0.02 mm; max variation across coil ≤ 0.01 mm).

- Mechanical property range (yield, tensile, elongation) — not single values but acceptable bands.

- Surface finish class (specify Ra target or “bright finish / skin-passed”) and any pretreatment required.

- Edge/burr criteria after slitting (burr height limit, acceptable edge type).

- Batch traceability: heat numbers, MTC with chemical & mechanical test results.

- First-coil acceptance: requires a signed first-coil report and pre-shipment photos for the first delivery.

- Packaging and handling specifics (protective film, interleave) for prepainted or plated surfaces.

These items convert vague expectations into verifiable acceptance criteria — and they make it harder for disputes to become “he said / she said” episodes.

How to Evaluate Suppliers on Steel Quality

When assessing a supplier, ask for evidence — not promises:

- Provide recent MTCs and a description of how they control width/thickness variation.

- Show SPC charts for a representative product line (thickness, flatness, hardness).

- Explain slitting and knife maintenance practices; ask about burr control procedures.

- Demonstrate trial support: willingness to supply trial coils and run a joint first-run test.

- Supply chain transparency: can they identify mill sources and commit to heat/coil traceability?

Suppliers who deliver this documentation are demonstrating operational maturity — and that maturity protects your line.

Schlussfolgerung

Small hardware stamping parts are highly sensitive to steel quality because their geometries and production routes leave little room for material variability. For procurement teams, the remedy is straightforward: translate functional needs into measurable material criteria, demand documentation and first-coil validation, and select suppliers who can demonstrate stable process controls. When you treat steel quality as a set of verifiable attributes rather than a vague expectation, you dramatically reduce scrap, tooling downtime, and the risk of costly rework — and you make your sourcing decisions defensible to engineering and finance alike.

Über Weijunli Steel

Weijunli Steel is a professional steel coil and plate supplier and processor serving B2B manufacturers worldwide. Backed by stable mill resources, precision slitting, and strict quality control, we specialize in Maßgeschneiderte Stahllösungen for small stamped hardware and high-tolerance components.

Our factory supports customized steel grades, thickness control, surface finish, edge/burr requirements, and full heat- and coil-level traceability. From material selection and trial coils to documentation and first-coil validation, Weijunli Steel helps OEMs reduce scrap, stabilize production, and achieve predictable, high-yield stamping performance by delivering excellent steel quality.

Practical FAQ for a Low-Risk Steel Quality RFQ

Q1: What material grade should I specify?

A1: Always define the exact grade and standard (e.g., SPCC, DC01). This ensures predictable formability, surface quality, and supplier accountability.

Q2: How should thickness and tolerance be stated?

A2: Specify nominal thickness together with allowable tolerance. Tight tolerance reduces stamping variation and improves dimensional consistency.

Q3: Do I need to define mechanical properties?

A3: Yes. Always request acceptable ranges for yield strength (YS), tensile strength (TS), and elongation (El), not just typical values.

Q4: What surface finish should be required?

A4: State surface requirements clearly, such as Ra limits, bright finish, or skin-passed condition, especially for plated or painted parts.

Q5: How should edge quality be specified?

A5: Define maximum allowable burr height and edge type (slitted or sheared) to prevent cracking and tool wear in stamping operations.

Q6: When should coating requirements be included?

A6: If corrosion resistance or appearance is critical, specify the coating type explicitly (GI, GL, or prepainted steel).

Q7: Is first-coil acceptance necessary?

A7: For new suppliers or new applications, first-coil approval is strongly recommended to verify performance before full production.

Q8: Why are MTC and batch traceability important?

A8: Material Test Certificates and batch traceability allow root-cause analysis and protect buyers in case of quality disputes.

Q9: What packaging details should be clarified?

A9: Define protective measures such as film, interleaving paper, desiccants, or wooden cradles to avoid transit damage.