تغطي المعالجة السطحية للصلب المعالجات الميكانيكية والكيميائية والكهروكيميائية والكهربائية والطلاء - وتهدف إلى تشطيب الفولاذ وحماية الفولاذ. المعالجة السطحية لها تأثير كبير على خصائص أداء الفولاذ، بما في ذلك مقاومة التآكل، والتصاق الطلاء، وأداء التآكل، وحتى الخصائص الكهربائية.

سواء كنت تقوم بتحديد العوارض الهيكلية أو ألواح السيارات أو قطع غيار الماكينات الدقيقة، فإن المعالجة السطحية الصحيحة تقلل من تكاليف الصيانة وتحسن السلامة وترفع الجودة المتصورة. في هذه المدونة، Weijunli Steel، وهي شركة مورد رائد في مجال الصلب, لديه معلومات عن المعالجة السطحية للصلب لمشاركتها معك.

لماذا تعتبر معالجة سطح الفولاذ حاسمة

يمكن أن تحقق المعالجة السطحية عالية الجودة للصلب بشكل أساسي الوظائف الرئيسية الأربع التالية:

- توفير حماية فعالة: حماية الفولاذ من الصدأ والتآكل الكيميائي.

- تعزيز المتانة: تحسين متانة المكونات من خلال تعزيز مقاومة التآكل أو مقاومة الخدوش.

- تنفيذ المتطلبات الوظيفية: منح خصائص وظيفية محددة مثل العزل الكهربائي أو التوصيل المعزز.

- تعزيز جماليات المنتج: توفير مؤثرات جمالية متنوعة تتراوح بين التلميع بالمرآة والملمس غير اللامع.

اختيار خطأ تعد المعالجة السطحية سببًا جذريًا شائعًا لـ الفشل المبكر, مثل تقشير الطلاء أو تآكل السطح أو ضعف أداء اللحام. ولذلك، ينبغي اعتبار قرارات التصميم المتعلقة بالتشغيل الآلي الدقيق جزءًا من التصميم الهندسي، وليس مكملاً له بعد ذلك

الأنواع الشائعة من المعالجة السطحية للصلب

فيما يلي العمليات الصناعية الأكثر استخدامًا على نطاق واسع، مرتبة حسب المبدأ وحالات الاستخدام النموذجية.

المعالجات الميكانيكية

تعمل المعالجة الميكانيكية على تغيير شكل سطح الفولاذ من خلال وسائل فيزيائية، وتستخدم بشكل أساسي للتنظيف وتحسين الالتصاق:

- التفجير بالرصاص/السفع بالرمل: تعمل الوسائط الكاشطة على تنظيف القشور وتوفر ملمسًا كاشطًا يحسِّن من التصاق الطلاء. شائع قبل الطلاء أو الطلاء بالمسحوق أو الجلفنة بالغمس الساخن.

- التلميع/التلميع/التلميع: ينتج أسطحاً عاكسة ومشرقة لتزيين الفولاذ المقاوم للصدأ أو الأجهزة الاستهلاكية.

- التنظيف بالفرشاة/الطحن (تشطيب بالفرشاة): يخلق حبيبات موجهة، خاصة للألواح التزيينية والأثاث.

المعالجات الكيميائية

تغير المعالجة الكيميائية التركيب الكيميائي لسطح الفولاذ أو تزيل الأكاسيد من خلال المحلول:

- التخليل: الحمامات الحمضية (H₂SO₄SO₄)، التي تستخدم عادةً في الصلب المدرفل على الساخن، تزيل قشور وأكاسيد الطاحونة من الصلب المدرفل على الساخن قبل المعالجة النهائية.

- الفوسفات: يحول السطح إلى طبقة فوسفاتية تحسن بشكل كبير من التصاق الطلاء ومقاومة التآكل المؤقت - تُستخدم عادةً في ألواح هياكل السيارات والأجهزة المنزلية.

- التخميل: خطوة أكسدة مضبوطة (غالباً ما تكون للفولاذ المقاوم للصدأ) تعمل على تثبيت طبقة واقية غنية بالكروم وتمنع الحديد الحر على السطح.

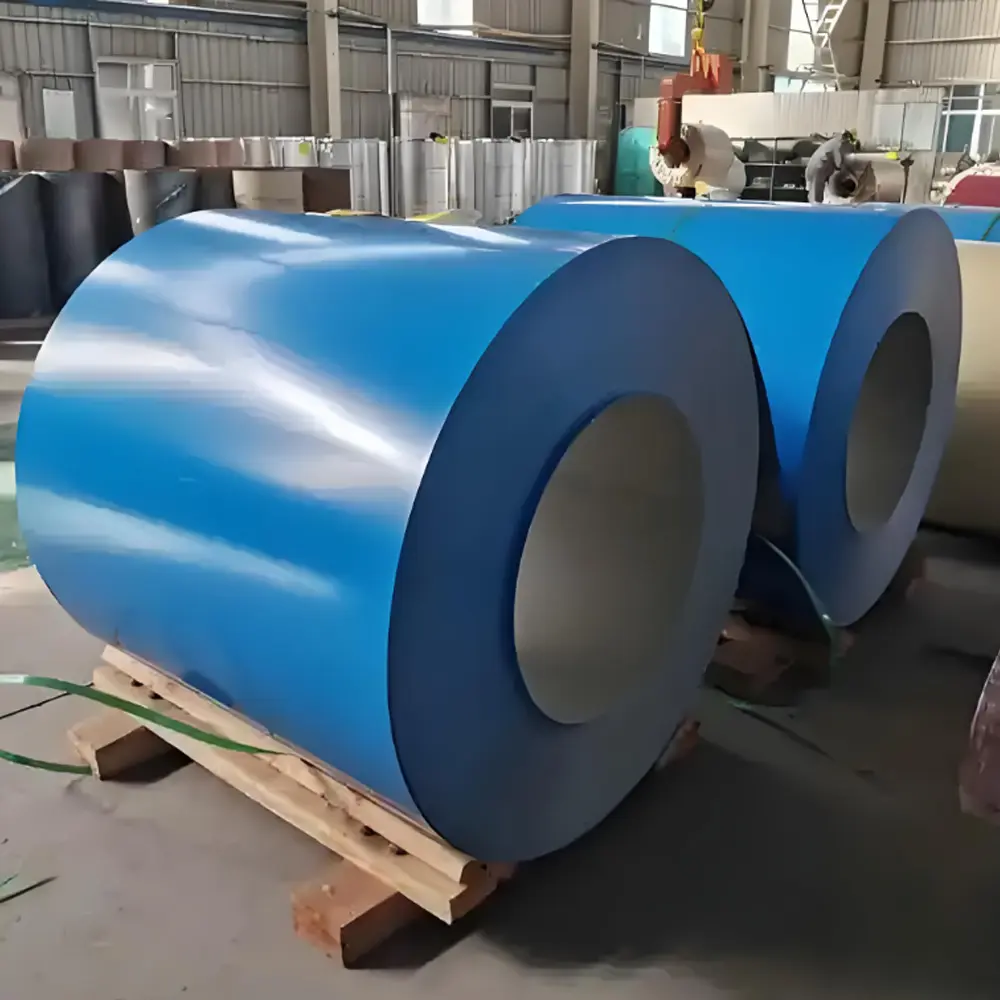

الطلاءات الكهروكيميائية والمعدنية

يشكّل هذا النوع من الطرق طبقة واقية معدنية على سطح الفولاذ بواسطة التيار أو المعدن المنصهر بدرجة حرارة عالية:

- الطلاء بالكهرباء (الزنك والنيكل والكروم والقصدير): توفر الطبقات المعدنية الرقيقة والموحدة الحماية من التآكل والتشطيبات الزخرفية للمثبتات وأغطية الإلكترونيات والزخارف.

- الجلفنة الكهربائية مقابل الجلفنة بالغمس الساخن: تعمل الجلفنة الكهربائية على ترسيب طبقة رقيقة نسبياً من الزنك تحت تيار متحكم فيه؛ أما الجلفنة بالغمس الساخن فتغمر الصلب في الزنك المنصهر، مما ينتج عنه طلاء أكثر سمكاً ومتانة مثالي للهياكل الخارجية.

- الطلاء بالغمس الساخن بالألمنيوم والتعليب: تُستخدم للتطبيقات ذات درجات الحرارة العالية أو الملامسة للأغذية.

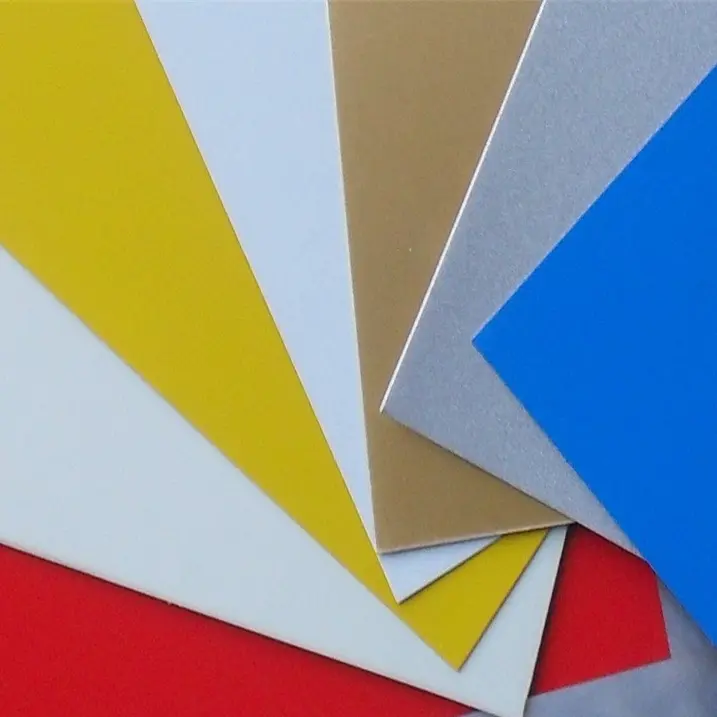

الطلاء العضوي والبودرة

وهي عبارة عن طلاءات غير معدنية توفر الحماية واللون والجماليات في المقام الأول:

- طلاء سائل (إيبوكسي، بولي يوريثان): طبقات حماية متعددة الاستخدامات مع تحكم قوي في اللون واللمعان. يعتمد الاختيار على مقاومة الأشعة فوق البنفسجية والكيميائية والتآكل.

- طلاء المسحوق: مسحوق إلكتروستاتيكي معالج بالحرارة وخالٍ من المذيبات الحرارية ومتين ويستخدم على نطاق واسع للأثاث والعناصر المعمارية والأجهزة المنزلية.

تشطيبات متقدمة ومتخصصة

تمثيل المتطلبات التقنية العالية والمتطلبات الوظيفية الخاصة:

- ترسيب البخار الفيزيائي (PVD): أغشية زخرفية صلبة ومزخرفة مفرغة من الهواء (مثل نيتريد التيتانيوم) للأجهزة المتطورة ومكونات التآكل.

- التلميع الكهربائي: إذابة أنودية تعمل على تنعيم القمم الدقيقة؛ وهي مثالية للفولاذ المقاوم للصدأ الطبي والغذائي لأنها تقلل من التصاق البكتيريا.

- طلاءات النانو وطبقات التنظيف الذاتي: تقنيات ناشئة تضيف خصائص طاردة للماء أو مضادة للميكروبات دون تراكم طبقة سميكة.

اختبار ومعايير المعالجة السطحية للصلب

مراقبة الجودة أمر بالغ الأهمية في المعالجة السطحية. ولضمان متانة وسلامة وامتثال المنتج النهائي، من الضروري عادةً إجراء الاختبارات الرئيسية التالية والامتثال للمعايير الدولية المقابلة.

اختبار مقاومة التآكل:

- اختبار رش الملح (ASTM B117/ISO 9227): طريقة اختبار التآكل المعجل المستخدمة لتقييم مقاومة التآكل لأنظمة الطلاء مثل الطلاء والطلاء الكهربائي.

الكشف عن سُمك الطلاء:

- أداة القياس: استخدم مقاييس السُمك المغناطيسية أو مقاييس سُمك التيار الدوامي.

- الغرض: التأكد من أن سمك الطبقة الواقية يفي بمتطلبات المواصفات الهندسية (المواصفات)، وهو مؤشر رئيسي لقياس مقاومة التآكل.

اختبار الالتصاق:

- الطرق الشائعة: القطع المتقاطع والسحب.

- الغرض: للتحقق من قوة الترابط بين الطلاء أو طبقة الطلاء والركيزة الفولاذية، ومنع الطلاء من التقشر أثناء الاستخدام.

معايير الصناعة المهمة:

معايير الصناعة هي الأساس لضمان قابلية التشغيل البيني العالمي واتساق جودة المنتجات. وفيما يلي المعايير المشتركة.

- وتحدد معايير الجلفنة بالغمس الساخن، مثل ASTM A123/ISO 1461، متطلبات السماكة والتوحيد والالتصاق والاختبار للطلاء المجلفن بالغمس الساخن.

- وتحدد معايير الطلاء المطلي بالكهرباء، مثل ASTM B633، على وجه التحديد أنواع وسماكات ومتطلبات أداء طلاء الزنك المطلي بالكهرباء.

- تُستخدم معايير الاختبار العامة، مثل ASTM B117، لتوجيه عمليات اختبار محددة.

كيفية اختيار المعالجة السطحية المناسبة للصلب

ضع في اعتبارك هذه العوامل الأربعة:

- البيئة: يتطلب التعرض الخارجي والساحلي والكيميائي التعرض للمواد الكيميائية طلاءات أكثر سمكاً وأضحيّة (الجلفنة بالغمس الساخن + الطلاء).

- الوظيفة: هل يتطلب الجزء عزلًا كهربائيًا أو توافقًا مع الطعام أو مقاومة عالية للتآكل؟ اختر الطلاءات وفقًا لذلك (الأغشية غير العضوية العازلة، الطلاء الكهربائي، الطلاء بالبطاريات الصلبة PVD).

- المظهر: قد تحتاج التطبيقات التزيينية إلى طلاء مرآة أو PVD أو طلاء مسحوق ثابت اللون.

- التكلفة والصيانة: موازنة التكلفة الأولية للطلاء مقابل صيانة دورة الحياة (إعادة الطلاء والاستبدال).

أمثلة عملية:

- عضو الجسر الإنشائي → الجلفنة بالغمس الساخن + الطلاء.

- هيكل جسم السيارة → الطلاء الفوسفاتي + الطلاء الكهربائي (الطلاء الإلكتروني) + الطلاء.

- ناقل تجهيز الأغذية → غير قابل للصدأ المصقول كهربائياً.

- اللافتات الخارجية → ركيزة مجلفنة + مسحوق الطلاء.

الاتجاهات المستقبلية في معالجة أسطح الصلب

تتجه الصناعة نحو:

- مواد كيميائية منخفضة المركبات العضوية المتطايرة والمائية للامتثال البيئي.

- الطلاءات النانوية الرقيقة عالية الأداء تقلل من استخدام المواد مع إضافة وظائف (مضادة للقاذور ومضادة للتجمد).

- الطلاءات الذكية مزودة بمستشعرات مدمجة أو بخصائص المعالجة الذاتية لتقليل دورات الفحص.

الخاتمة

تعتبر معالجة أسطح الصلب قرارًا متعدد التخصصات يؤثر على المتانة والسلامة والجماليات وتكلفة دورة الحياة. وتتطلب العملية الصحيحة، سواءً كانت الجلفنة بالغمس الساخن أو الطلاء بالكهرباء أو الطلاء بالمسحوق أو التطورات الجديدة في الترسيب الفيزيائي للبخار (PVD)، مراعاة البيئة والاستخدام والميزانية. اطلب دائمًا شهادات المواد واختبارات الالتصاق واختبارات السُمك للمشاريع الحرجة. عند النظر في المشاريع المقدمة، أدرج صيانة دورة الحياة في مقارناتك.

حول ويجونلي ستيل

بصفتك مورد ومعالج فولاذ محترف, تقوم شركة Weijunli Steel بتشغيل خطوط إنتاج متطورة وأنظمة صارمة لمراقبة الجودة لضمان أن كل منتج يلبي المعايير الدولية. يدعم فريقنا الفني شركاءنا العالميين من خلال التخصيص المرن والتسليم السريع.

اختر منتجاتنا للبيع بالجملة و حل مخصص من الفولاذ المقاوم للصدأ, وستحصل على منتجات متميزة بأسعار تنافسية.