Selection is not merely a technical checkbox; it is a strategic decision that defines the integrity of your production line. HRPO steel (hot-rolled pickled & oiled) and cold-rolled steel each have clear advantages — but they suit very different part profiles and production strategies in hardware stamping.

In this article, Weijunli Steel, a leading steel supplier and processor, gives procurement and engineering teams a practical decision framework so you can specify the correct material, avoid costly field failures, and write RFQs that actually protect production.

Quick Answer: Can HRPO Steel Be Used for Stamping?

Yes.

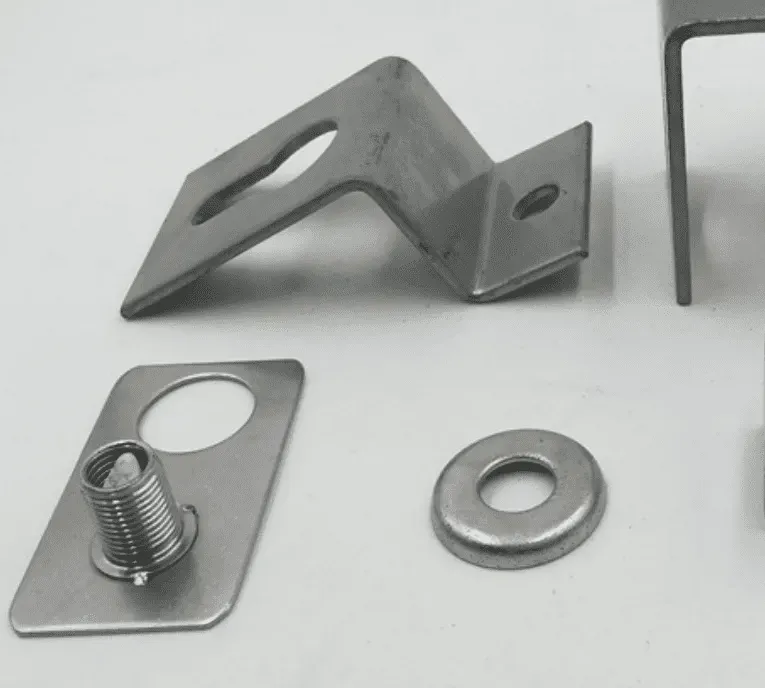

HRPO steel is perfectly usable for many stamped hardware parts. It’s especially cost-effective for structural, mid-thickness components such as U/L brackets, mounting plates, reinforcement clips, and other parts that prioritize strength and weldability over cosmetic finish (typical gauges ~2.0–6.0 mm). However, if your part requires dense perforations, tight assembly tolerances, deep single-hit drawing, or high-gloss electroplating, cold-rolled steel is the safer choice.

HRPO Steel Vs Cold Rolled Steel Choice

Hardware stamping failures usually look the same on the shop floor: cracks at radii, excessive springback, oversized burrs, poor paint or plating adhesion, and whole batches rejected because upstream coil variation broke an otherwise validated die. Common procurement mistakes include issuing RFQs like “SPCC 1.0 mm” or “HRPO 3.0 mm” — too little detail.

The correct selection is not a commodity buy; it’s a process decision tied to forming severity, surface finish needs, and total cost of ownership.

Core Differences That Matter to Buyers

Surface quality & plating risk

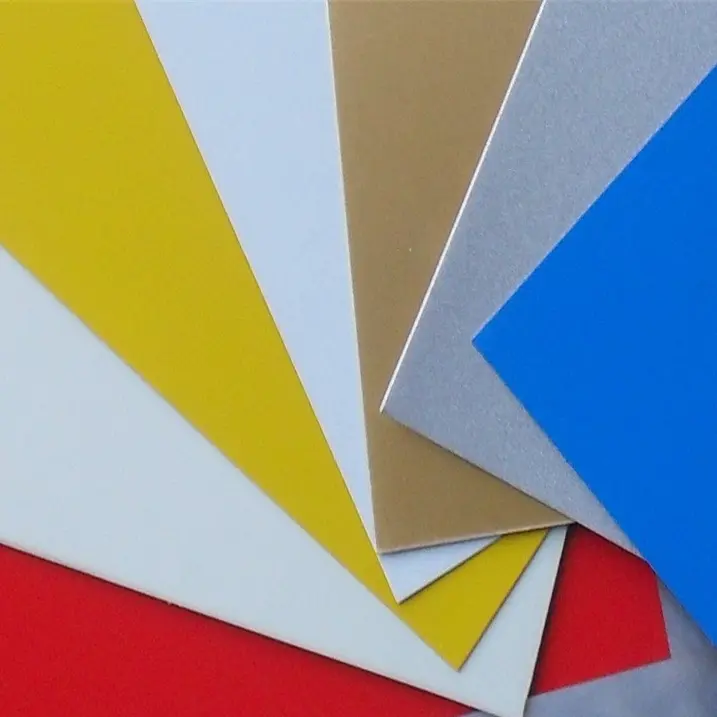

Cold-rolled steel has a finer, more uniform surface (lower Ra) and better flatness, which is why it’s the default for plated or highly visible parts. HRPO steel is acid-pickled and oiled, so it’s cleaner than black hot-rolled steel but may still display acid-wash marks, micro-pits, or uneven oil. If you plan chrome or mirror finishes, default to cold rolled.

Thickness range & cost efficiency

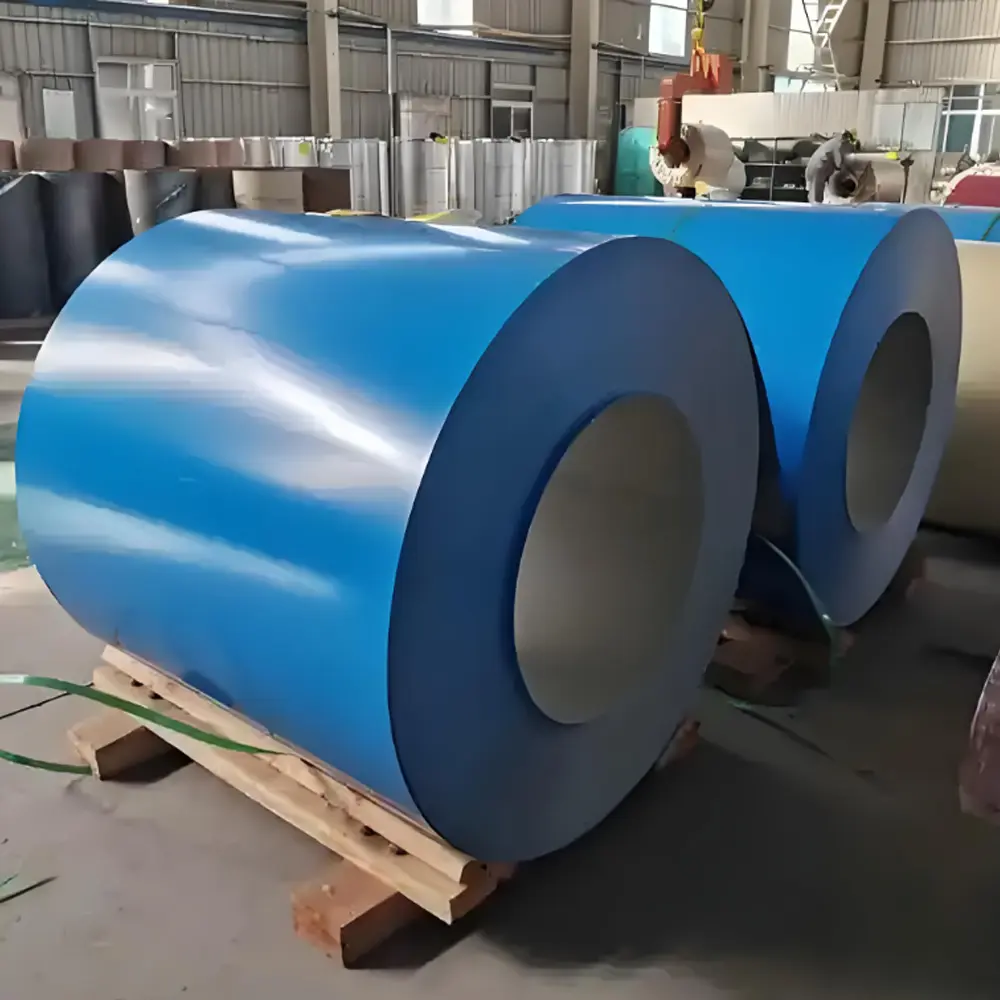

Cold rolled dominates thin gauges (≈0.3–3.0 mm). HRPO steel typically covers thicker ranges (≈1.5–8.0 mm and up) at a better cost per functional part. For thick brackets, reinforcement plates, and welded assemblies, HRPO steel often offers the best balance of performance and price.

Flatness, dimensional stability & batch consistency

Cold rolled processes produce tighter thickness tolerances and superior plate geometry; that reduces springback and hole positional drift. HRPO steel can show greater plate-to-plate variability and residual stress — a critical factor if assembly gaps are small or hole tolerances are tight.

Formability & cracking risk (it’s about grade, not blanket rules)

Some HRPO steel grades are available in deep-draw equivalents (DD11–DD14 equivalents) and can form well. But common structural HRPO grades (Q235/SS400 family) have more variable elongation and higher cracking risk. Cold-rolled deep-draw grades (SPCC/DC01 variants) deliver a more predictable forming window for single-hit draws and tight radii.

Burr control & tooling wear

Because HRPO steel can be harder and have rougher edge behavior after slitting, tool wear and burr size may increase, translating to higher die maintenance. For high-speed progressive dies and continuous stamping, cold-rolled typically reduces hidden tooling costs.

Total cost vs hidden cost

On a per-ton basis, HRPO steel is usually cheaper, but the true metric is per-part cost: scrap, rework, die life, and finishing expenses can make an apparently cheaper material more expensive in practice. Always model per-part Total Cost of Ownership, not just unit material price.

Summary

| Feature / Parameter | Cold-Rolled Steel (CR) | HRPO Steel (Hot Rolled Pickled & Oiled) |

| Surface Quality | Superior smoothness (Low Ra); default for chrome or mirror finishes. | Acid-pickled; may show micro-pits or wash marks; unsuitable for mirror plating. |

| Thickness Range | Optimized for thin gauges (0.3 – 3.0 mm). | Best for thicker structural parts (1.5 – 8.0 mm+). |

| Dimensional Precision | Tighter tolerances; minimal springback and high batch consistency. | Higher variability in thickness and residual stress; risk of hole drift. |

| Formability | High predictability; ideal for deep-draw (SPCC/DC01) and tight radii. | Grade-dependent; structural grades (Q235) carry higher cracking risks during forming. |

| Tooling & Maintenance | Lower burr risk; extends die life in high-speed progressive stamping. | Higher surface friction and edge hardness; increases tool wear and maintenance. |

| Economic Value | Higher unit price, but lower hidden costs (rework/finishing). | Tighter tolerances, minimal springback, and high batch consistency. |

When HRPO Steel Is the Right Choice

Use HRPO steel for parts that share these traits:

- Structural function over cosmetic finish (mounting plates, reinforcements).

- Moderate-to-thick gauges where strength and weldability matter.

- Surface defects are acceptable because powder coat or paint will cover them.

- Welding, drilling, or machining are primary operations after stamping.

In these cases, HRPO steel delivers performance at a lower material cost.

When Cold-rolled Is the Safer Option

Specify cold-rolled steel when:

- Parts are visible and require high cosmetic quality or electroplating.

- Designs include dense perforations, tight hole patterns, or precision assembly.

- Processes involve high-speed blanking, deep drawing, or progressive dies where burr control and die life are essential.

Cold rolling limits process variability and hidden downstream costs in these applications.

How to Write an RFQ for Low-risk HRPO Stamping

Avoid “HRPO 3.0 mm” and replace it with measurable acceptance criteria:

- Grade/equivalent: specify DD11/DD12/DD13/DD14 or the mill equivalent if deep-draw is required.

- Thickness & tolerance: e.g., 3.0 mm ±0.05 mm; max across-coil variation.

- Mechanical window: acceptable ranges for YS / TS / El (not single nominal values).

- Surface spec: pickling class, permitted pitting, oil type/amount, Ra targets if relevant.

- Edge condition: slitted or sheared; max burr height after slitting.

- Coil geometry: ID/OD, coil weight limits.

- Handling & packaging: protective film, interleave, desiccant for long transit.

- Validation: first-coil trial stamping and first-article inspection with signed acceptance.

- Traceability: MTC and heat/coil IDs for every delivery.

Insist on a trial coil and a documented first-article sign-off before volume release. That one step prevents the most common production surprises.

Decision Guide — One Sentence for Buyers

- Need appearance, plating, precision, and predictable forming → choose cold-rolled steel.

- Need strength, thickness, cost efficiency, and surface that can be painted → HRPO steel is a practical choice — provided you lock mechanical specs, surface acceptance, and trial validation into the contract.

Conclusion

HRPO steel is not “cheap junk” — it’s a cost-optimized structural material that works extremely well when matched to the right parts and when procurement controls the spec. Cold-rolled steel is not a wasteful luxury; it is the reliable option for precision, cosmetic, and high-yield stamping programs. The professional buyer doesn’t pick by price: they pick by the spec set that minimizes scrap, stabilizes tooling costs, and protects production uptime.

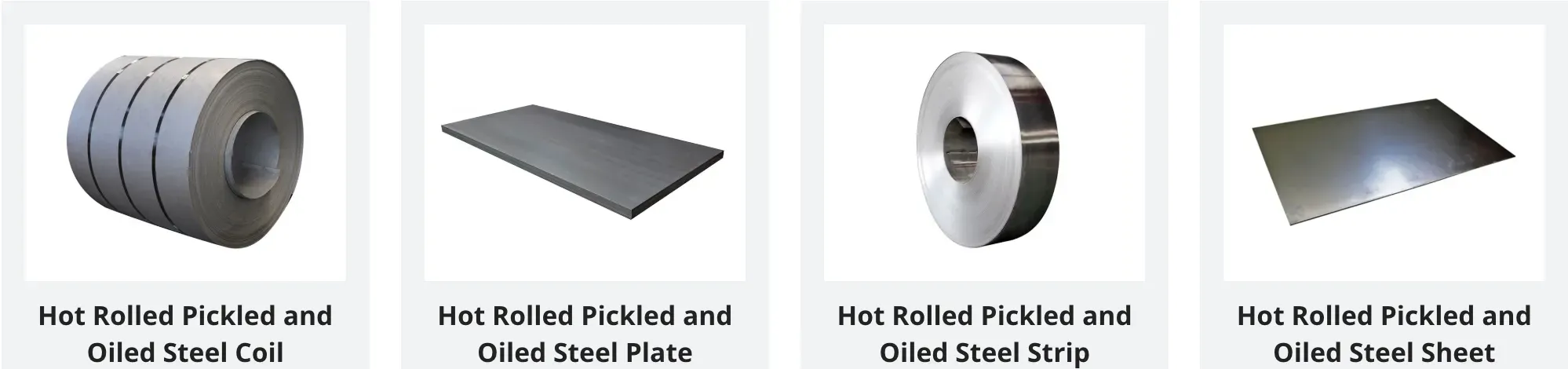

About Weijunli Steel

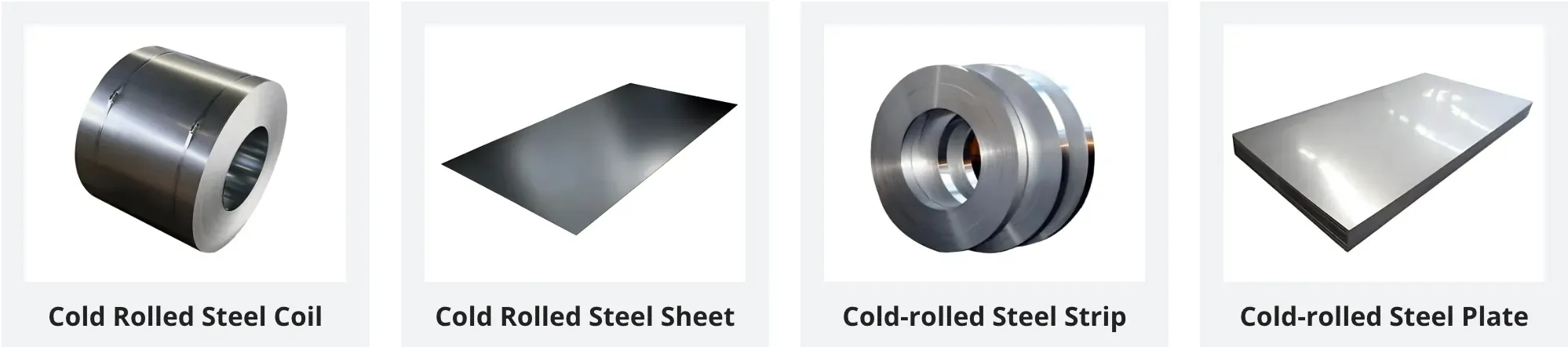

Weijunli Steel is a professional steel supplier and processing partner focused on supplying wholesale HRPO steel and wholesale cold-rolled steel for stamping and fabrication industries. We support B2B buyers with stable batch-to-batch consistency, controlled mechanical properties, and reliable coil traceability to reduce die adjustment, scrap, and production interruptions.

Beyond standard supply, we offer custom steel solutions including slitting, cut-to-length, thickness tolerance control, surface requirement matching, and export-ready packaging. Whether you source HRPO for structural brackets or cold rolled for precision parts, Weijunli helps you lock specifications into scale production with confidence.

FAQ

Q1: Can HRPO Steel Be Used for Precision-Punched Parts?

A1: Only if the HRPO grade is a deep-draw/low-carbon variant and the RFQ locks tight mechanical and thickness ranges; otherwise, cold rolled is safer.

Q2: Can HRPO Steel Be Electroplated?

A2: It’s possible but not recommended for high-gloss plating — pickling marks and surface variability often show through plated finishes.

Q3: Which Is Better for Progressive Dies and High-Speed Stamping?

A3: Cold rolled is generally better due to lower burrs and gentler die wear.

Q4: How Do I Map DD11–DD14 to SPCC/DC01?

A4: Don’t rely on names alone — request mechanical bands (YS/TS/El) and accept equivalent properties rather than a grade name.