Power transformers sit at the heart of electricity transmission and distribution. Their efficiency and reliability directly affect grid losses, operating costs, and asset life. That’s why transformer designers specify grain oriented electrical steel: its directionally optimized magnetic properties deliver far lower core losses and higher flux capability than any practical alternative, making it the industry standard for transformer cores.

Today, please let Weijunli Steel, a leading steel supplier and processor, tell you the reasons.

What Makes Grain Oriented Electrical Steel unique?

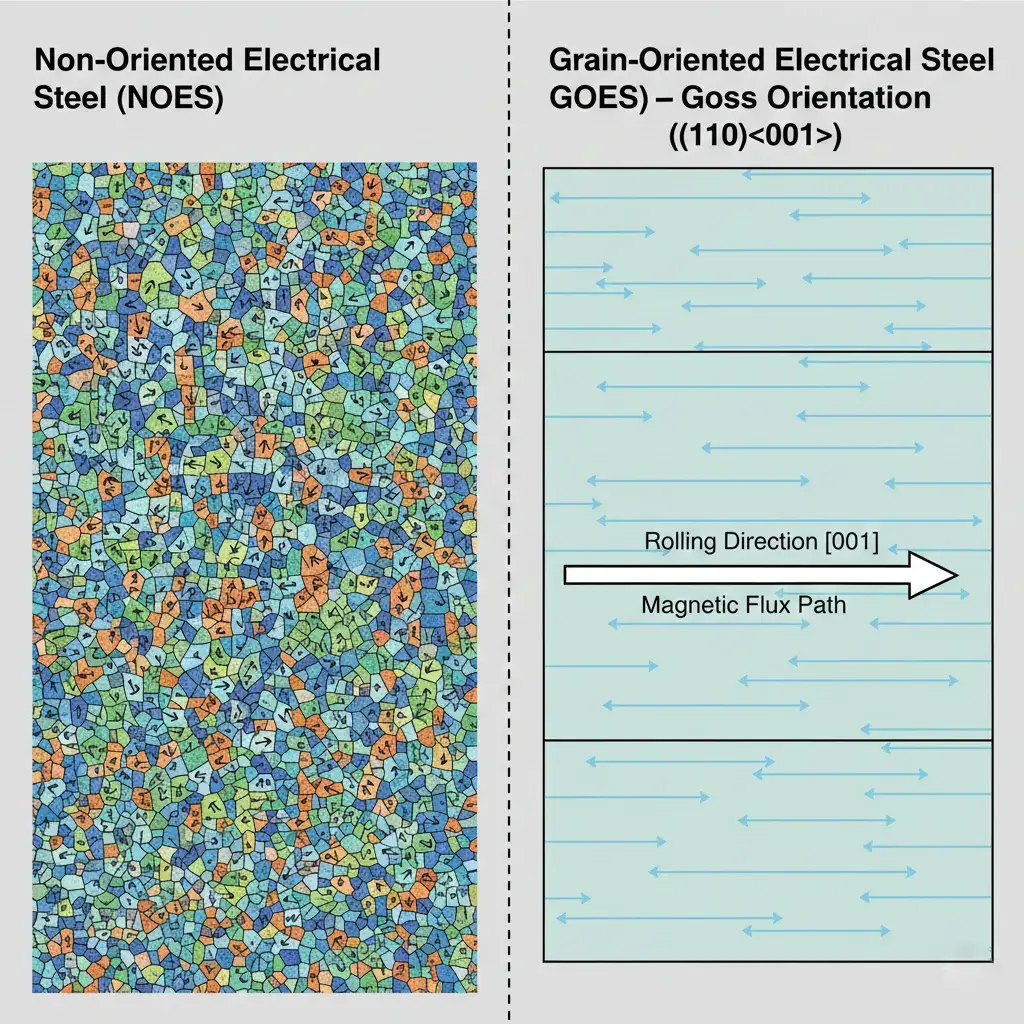

The defining trait of grain oriented electrical steel is its engineered crystal texture — commonly the Goss orientation ({110}<001>) — produced by controlled thermo-mechanical processing and secondary recrystallization. Instead of random grain orientation, very large grains align with the rolling direction. The result is a near single-crystal pathway for magnetic flux along that direction, which dramatically reduces hysteresis and eddy-current losses when magnetized parallel to the rolling direction.

Two combined effects produce the performance advantage:

- a dramatic reduction in magnetic hysteresis (lower hysteresis loss), and

- a pathway that supports higher magnetic flux density with minimal additional loss.

These properties are precisely what transformer cores require, because transformer laminations are stacked so the rolling direction aligns with the dominant flux path.

Magnetic Advantages that Matter for Transformers

Extremely low core loss

Core loss is energy converted to heat inside the iron core — it represents no useful work and is a continuous operating expense. Grain oriented electrical steel minimizes both hysteresis and eddy-current components of core loss at power frequencies (50/60 Hz), so transformers run cooler and consume less no-load power.

High magnetic permeability in the rolling direction

High permeability reduces the magnetizing current needed to establish flux, improving regulation and reducing reactive power demands on the grid. In practical terms, a transformer using GOES can be smaller and more efficient for the same rating.

Stable performance under heavy-duty and high flux

Large power transformers often operate near high flux density for compact designs. GOES sustains higher flux densities with lower incremental loss than non-oriented steels, enabling compact, high-capacity designs with acceptable thermal margins.

Lower audible noise and magnetostriction

Because GOES channels flux more uniformly, magnetostrictive effects (which cause hum and vibration) are reduced, helping utilities meet noise regulations and improving public acceptance in populated areas.

Why Non-Oriented Steel Won’t Do for Power Transformers

Non-oriented electrical steel is designed to provide roughly isotropic magnetic properties in all directions, making it the material of choice for rotating machines (motors and generators) where the magnetic flux rotates. In power transformers, however, the flux flows almost exclusively in one direction (along the limbs and yokes of the core). Substituting NOES for grain oriented electrical steel (GOES) in such applications typically results in:

- 2–4 times higher core losses at typical operating flux densities (1.7–1.9 T)

- Significantly higher no-load losses and operating temperatures

- The need for a substantially larger and heavier core (often 20–50 % more steel by weight) to keep temperature rise and losses within acceptable limits

- Higher magnetizing current and reactive power demand

- Increased audible noise due to higher magnetostriction

These penalties make NOES economically and technically uncompetitive for utility-scale power transformers rated from a few MVA upwards, where lifetime energy costs far exceed the initial material cost. As a result, virtually all modern power transformers worldwide use GOES for the core, while NOES is restricted to small distribution transformers (typically <1–2 MVA) or special applications where cost outweighs efficiency considerations.

Efficiency Gains & Grid-Level Impact

The efficiency advantage of GOES scales: a small percentage reduction in transformer no-load loss multiplied across millions of transformers yields substantial national energy savings. Fewer losses mean lower waste heat, reduced cooling requirements, longer insulation life, and lower transformer replacement frequency. For utilities, selecting GOES grades with lower core loss translates into measurable OPEX savings and improved system capacity.

Applications Where Grained Oriented Electrical Steel is Unrivaled

The primary and near-exclusive domains for grain oriented electrical steel are transformer cores across sizes:

- Transmission and distribution transformers (power and substation cores)

- Large autotransformers and generator step-up transformers

- Special high-efficiency transformers for data centers, industrial plants, and renewable-energy plants

GOES may also appear in certain large reactors and inductors where unidirectional flux and ultra-low loss are required.

Standards, Grades and What Specifiers Must Request

When specifying GOES, engineers should call out:

- Loss at specific flux and frequency (e.g., W/kg @ 1.7 T, 50 Hz)

- Grade designation (Hi-B, ultra-low loss variants)

- Thickness and coating type (for punching and lamination stacking)

- Traceability and test reports (loss curves, permeability curves, MTC)

Relevant standards include IEC/EN and national norms; always require supplier loss curves rather than only grade names.

Supply Chain and Practical Challenges

GOES production is capital-intensive and technically demanding. A limited number of mills can produce highest-grade GOES, which creates supply chain sensitivity and price volatility. Transformer manufacturers mitigate risk by qualifying multiple suppliers, holding inventory, and planning orders well ahead of project schedules.

Conclusion

For grid-scale transformers, grain oriented electrical steel is not merely one option — it is the material standard. Its engineered grain orientation, enabled by sophisticated metallurgy and thermal processing, delivers the ultra-low core loss, high flux capability, and stable, low-noise operation that modern power systems demand. Selecting the right GOES grade and ensuring a reliable supply are essential steps toward building efficient, resilient electrical infrastructure.

About Weijunli Steel

Weijunli Steel is recognized as a leading steel supplier and processor, dedicated to delivering stable quality and long-term value for global buyers. We offer wholesale grain oriented electrical steel supply and support brands and industrial users with custom grain oriented electrical steel solution services designed around performance, efficiency, and application-specific needs.

Our facilities follow internationally aligned production standards, operating with high output capability and strict safety controls. This ensures every grain oriented electrical steel coil, sheet, or processed batch meets the consistency required for transformers, power equipment, and precision electrical applications. Backed by extensive industry experience, our team understands market expectations and produces materials that have been well received by clients worldwide.

If you seek a supplier you can trust, Weijunli Steel is equipped to support your projects with dependable quality and responsive service.