Many of us have heard about stainless steel in our lives all the time, but have no chance to learn it comprehensively, only knowing that its most common application is cookware due to its excellent corrosion resistance.

In this blog, with Weijunli Steel, a leading steel supplier and processor, we are going to learn about it from scratch, including but not limited to types, production process, and common applications, apart from cookware.

What is Stainless Steel

Stainless steel is an alloy of iron that contains at least about 10.5% chromium. The iron was protected by the thin, stable oxide layer generated by chromium on the metal’s surface.

In addition, nickel, molybdenum, and a precisely controlled carbon content, along with other elements such as manganese, will be added to adjust strength, formability, and tolerance to specific environments.

Eventually, a series of materials with different properties was formed.

5 Common Types of Stainless Steel

Austenitic Stainless Steel (300 Series)

The austenitic family is the most widely used category of stainless steel, known for its high levels of chromium and nickel. These metals provide excellent corrosion resistance, high ductility, and good weldability. Austenitic steels are generally non-magnetic and retain toughness even at cryogenic temperatures. 304 and 316 in the 300 series are the common grades and both widely used for their outstanding oxidation resistance and clean surface finish.

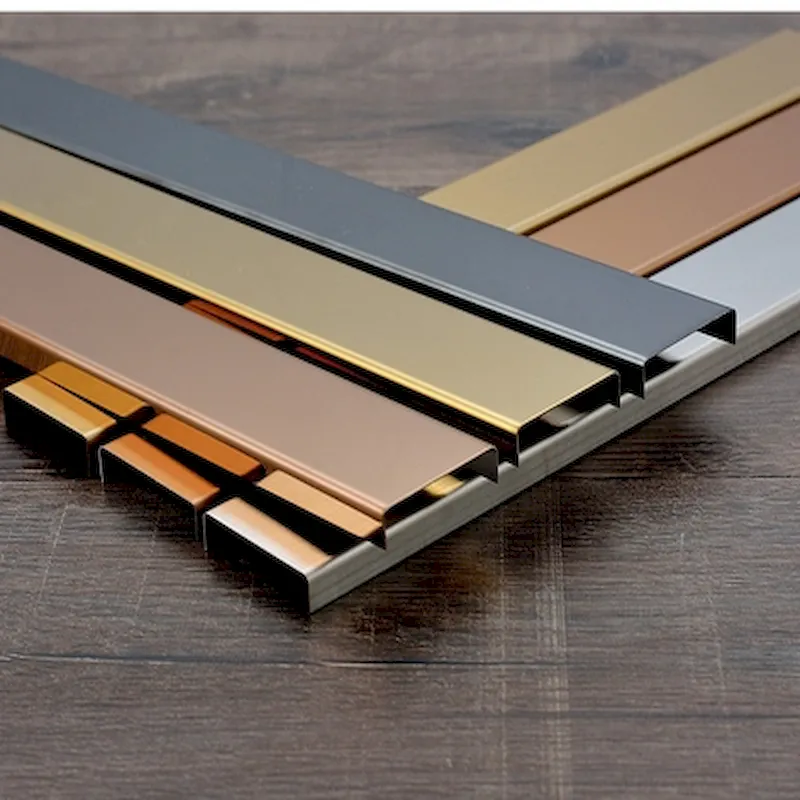

Applications: Industrial and household use like, cookware, kitchen sinks, food processing equipment, and architectural trim.

Ferritic Stainless Steel (400 Series)

This kind of steel is mainly chromium-based and contains little or no nickel. Therefore, it is magnetic and more cost-effective than austenitic grades. It has superior thermal conductivity. While its corrosion resistance is moderate, it offers good resistance to stress corrosion cracking. A popular grade, model 430, is valued for its balance between strength, ductility, and price.

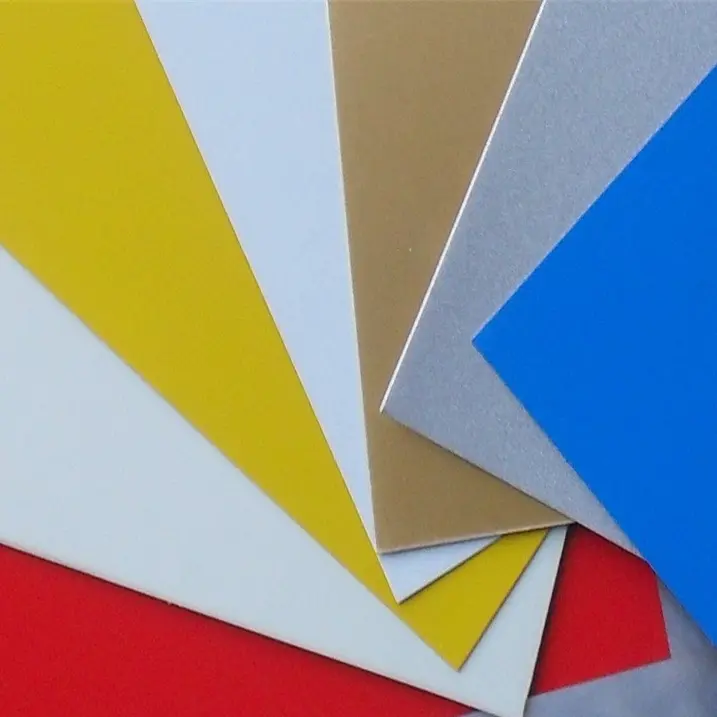

Applications: Decorative trims, automotive parts, and home appliances.

Martensitic Stainless Steel

The martensitic family stands out for its high carbon content. It can be hardened by heat treatment. These steels are magnetic, extremely strong, and resistant to wear. But their corrosion resistance is generally lower than that of austenitic types. Common grades include 410, 420, and 440, which are popular for their excellent hardness and edge retention.

Applications: Knives, cutting tools, and surgical instruments

Duplex Stainless Steel

Duplex stainless steel combines the structures of austenite and ferrite, then gains a unique balance of strength and corrosion resistance. With higher chromium and molybdenum content, duplex grades such as 2205 perform exceptionally well in chloride-rich environments. They provide nearly twice the strength of common austenitic grades while maintaining good toughness and weldability.

Applications: Chemical plants, oil and gas pipelines, and marine structures

Precipitation-Hardening (PH) Stainless Steel

It is engineered for extreme strength through a controlled heat treatment process that forms fine alloy precipitates in the metal’s structure. This process boosts mechanical properties while maintaining good corrosion resistance. A well-known example is SS 17-4PH, which combines exceptional tensile strength with good toughness and weldability.

Applications: Aerospace components, high-strength shafts, and precision fasteners

How Stainless Steel Is Made – Fundamental Processes

Step 1: The raw materials are precisely mixed with precision-melted alloy elements such as iron, chromium, and nickel, and then melted in an electric arc furnace. The key is to carry out secondary refining, such as argon oxygen decarburization (AOD), to achieve efficient decarburization and precise adjustment of chemical composition, which is fundamental to ensuring the corrosion resistance of materials.

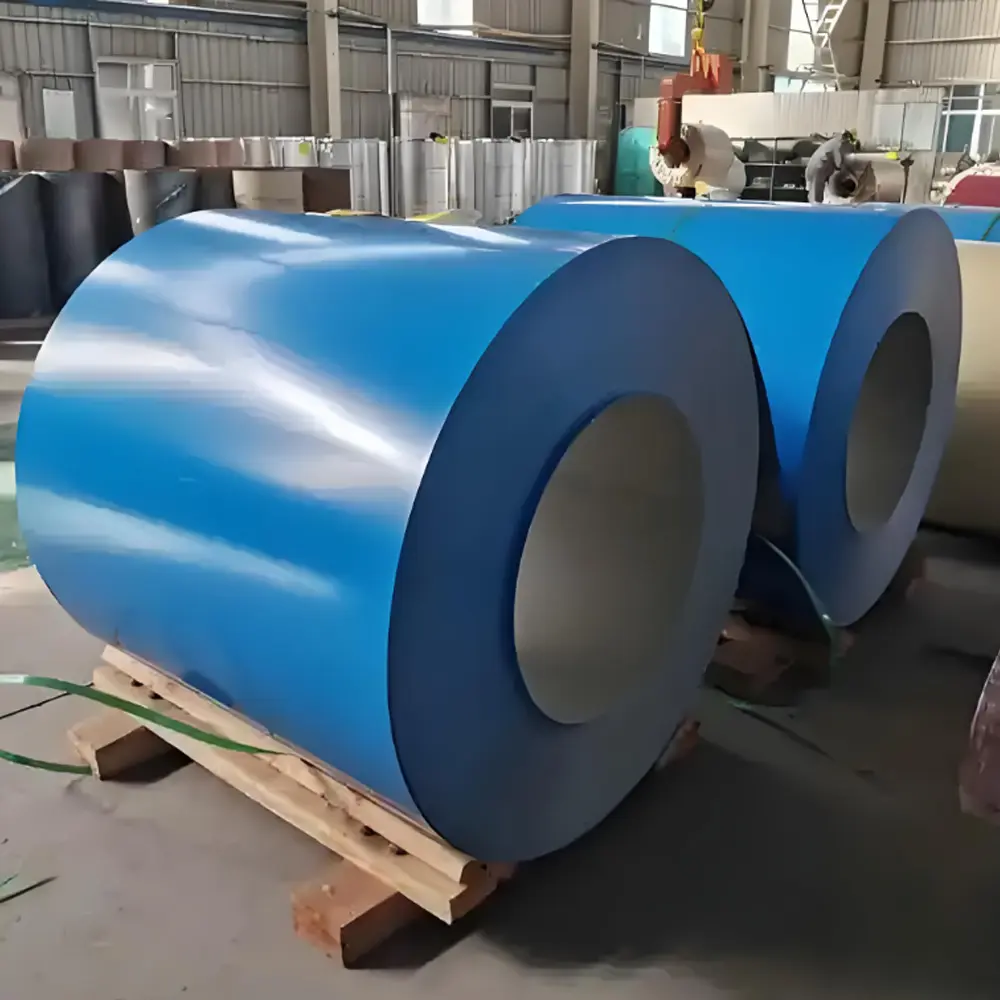

Step 2: Continuous casting and plastic deformation of molten steel form slabs through continuous casting to ensure uniform internal structure. Subsequently, rolling (hot and cold rolling) is carried out to precisely control the size, optimize the microstructure, and work hardening is achieved through cold rolling to improve strength.

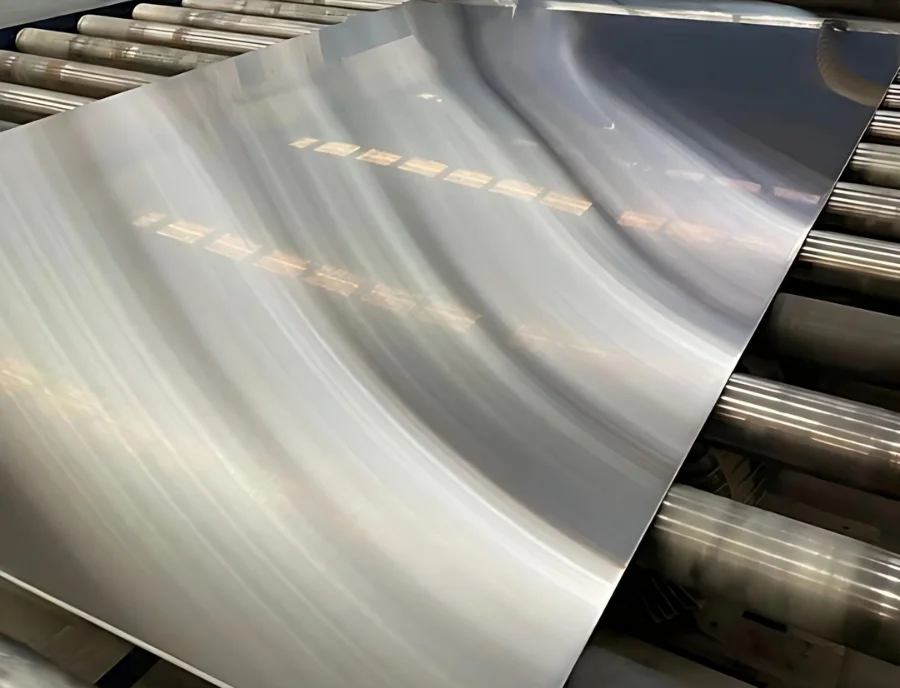

Step 3: Recovery and Passivation. Core Heat Treatment is annealing, which restores ductility (eliminates work hardening) through recrystallization. Subsequently, acid washing (Pickling) is carried out to remove the oxide scale, thereby restoring the key characteristic of stainless steel – passivation ability.

Step 4: Precision machining and certification. The material undergoes final surface precision machining (such as polishing or drawing) and comprehensive quality inspection and performance testing to ensure that the product meets all engineering and performance specifications.

Conclusion

Now, you know stainless steel is more than just cookware. They are used in many industrial sectors, like chemical plants and aerospace components. Each grade—ranging from austenitic to precipitation-hardening—is unique with its benefits usable under different conditions and specifications. Understanding how it is made and what characterizes its main grades can assist you in making good material choices that ensure safety, reliability, and long-term value.

About WJL Steel

As a professional steel supplier and processor, Weijunli Steel operates advanced production lines and strict quality control systems to ensure every product meets international standards. Our technical team supports global partners with flexible customization and fast delivery.

Choose our wholesale and custom stainless steel solution, and you will gain premium products at competitive prices.