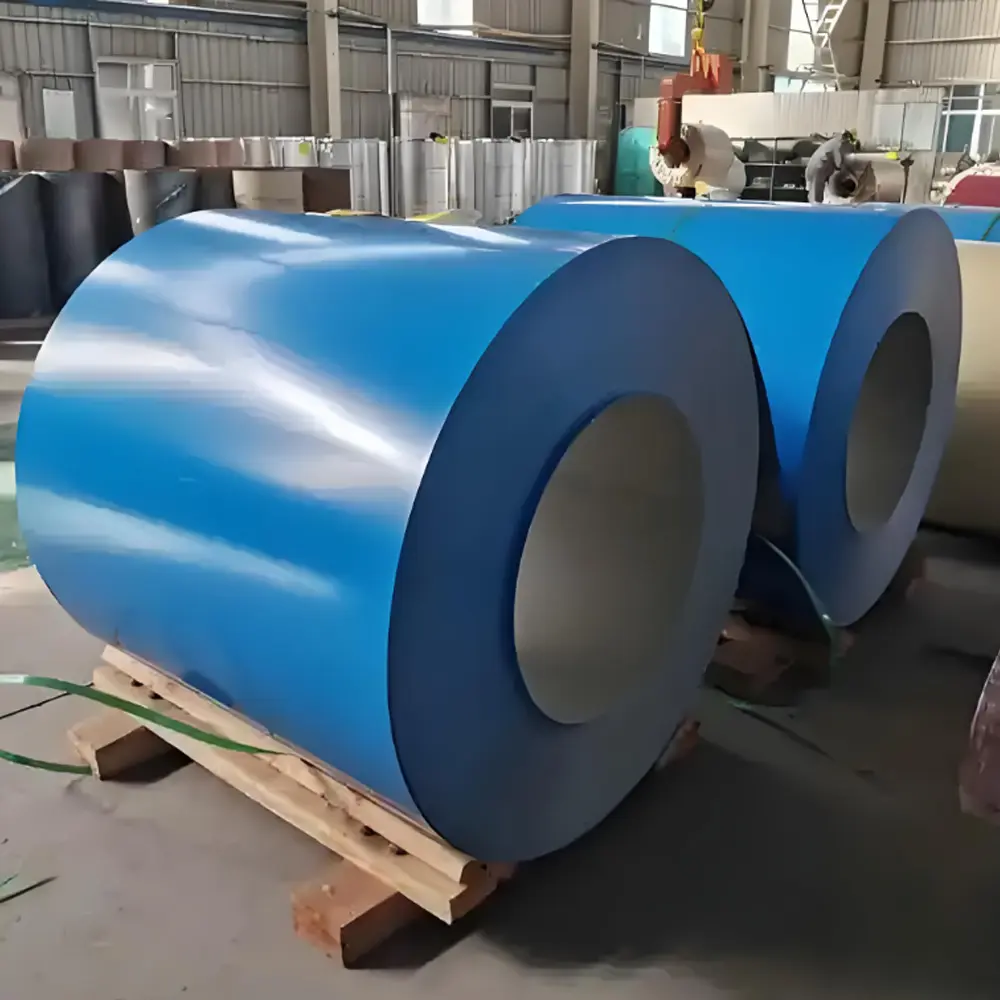

Hot rolled steel is a cost-effective construction material. This material is highly workable and available in large sizes — coils, plates, and structural sections — making it a staple for many applications.

In this blog, Weijunli Steel, a leading steel supplier and processor, will explain things you want to know about hot rolled steel.

Definition of Hot Rolled Steel

Hot rolled steel is a steel item that is manufactured by rolling steel in temperatures generally between 1000°C to 1250°C, above the recrystallization temperature of the steel. At such temperatures, the metal is soft and not very hard to mold into thick plates, wide coils, and structural forms. The process yields material that is cost-effectively produced in high volumes and best suited for construction, heavy machinery, and industrial fabrications.

Hot Rolled Steel Properties

Production temperature and process

Hot rolled steel is manufactured by heating semi-finished steel slabs, billets, or blooms in a reheating furnace and passing them through rolling mills while above the recrystallization temperature. The high temperature allows rapid thickness reduction with less force than would be required at ambient temperature. After final rolling, the material is subject to controlled cooling (often via laminar flow) to precisely manage the resulting microstructure before being coiled or cut into plates.

Surface and dimensional features

The key visible trait of hot rolled steel is mill scale—a dark, oxidized layer that forms during high-temperature processing. Surfaces may also display light rust, nesting marks (from coil contact), or slight pitting. Dimensionally, the material inherently has wider tolerances and poorer flatness than cold-rolled equivalents; thus, thickness variations and minor warpage are common, especially in thicker plates.

Microstructure and Mechanical Properties

Due to deformation occurring above the recrystallization temperature, hot rolled steel typically has a coarser grain structure, resulting in higher ductility and elongation, but typically lower yield strength, compared to cold rolled steel.

Processability and Downstream Processing

Hot rolled steel is easy to form, shear, weld, and bend, and has an extremely low risk of cracking. According to the final use, hot-rolled steel is usually subjected to further processing (acid washing to remove oxide scale, galvanizing for corrosion protection, or cold rolling to obtain stricter tolerances), depending on the end-use.

Advantages and Disadvantages of Hot Rolled Steel

Understanding its pros and cons can help you choose suitable materials for your project.

Advantages

- Cost effectiveness: With fewer precision machining processes and higher output, the ton cost of hot rolled steel is lower than that of cold-rolled steel.

- Large-scale production: capable of producing wide coils and thick plates that cannot be economically supplied by cold rolling.

- Good formability and weldability: Its high ductility enables it to be bent and welded in structural manufacturing.

- Flexible substrate processing: suitable for acid pickling, galvanizing, painting, or subsequent cold processing.

Disadvantages

- Poor surface finish: The oxide scale and roughness make it unsuitable for untreated visible or decorative applications.

- Large dimensional tolerance: If precise thickness and flatness are required, additional processing (cold rolling, machining) is needed.

- Mechanical performance differences: The mechanical performance differences of individual coils or sheets may be greater than those of strictly controlled cold-rolled products.

When to choose hot rolled steel: When cost, large cross-sectional size, and structural performance are more important than surface appearance and strict size control.

Applications of Hot Rolled Steel

Hot rolled steel’s combination of size availability, affordability, and mechanical properties makes it indispensable across industries:

- Construction & Infrastructure: Structural beams (I-beams, H-beams), columns, plates for bridges, and building frames. Structural grades (e.g., S235, S355 equivalents) are common.

- Heavy Equipment & Machinery: Bases, frames, and components for agricultural equipment, mining machinery, and industrial machines.

- Shipbuilding & Offshore: Hull plates, deck plates, and structural members where thickness, weldability, and toughness are required. Marine-grade hot rolled steels (e.g., AH36, DH36) are used after appropriate certification.

- Automotive & Transportation: Chassis components, cross-members, and certain stamped parts where surface finish is non-critical.

- Pipes, Tubes & Structural Sections: Hot rolled coils are often the feedstock for welded pipes and structural tubing used in construction and infrastructure.

- Energy & Storage: Steel structures for power plants, pressure vessel raw blanks (after further processing), and storage tanks.

Industry Standards for Hot Rolled Steel

The production and classification of hot rolled steel are strictly regulated by international and national standards to ensure consistency in chemical composition, mechanical properties, and testing methods. Understanding these standards is essential for global buyers and engineers when sourcing materials or verifying quality certifications.

Here are some of the most recognized hot rolled steel standards worldwide:

| Region | Standard System | Common Grades | Description / Application |

|---|---|---|---|

| United States (ASTM / AISI) | ASTM A36, ASTM A1011, ASTM A572 | A36, A1011, A572 Gr.50 | Widely used in construction, machinery, and automotive sectors. |

| Europe (EN) | EN 10025-2, EN 10111 | S235JR, S275JR, S355JR | Defines structural and low-carbon steels with good weldability. |

| China (GB) | GB/T 700, GB/T 3274 | Q235, Q345 | Covers general and structural-purpose hot rolled plates and sheets. |

| Japan (JIS) | JIS G3101, JIS G3132 | SS400, SPHC | Used for mechanical, construction, and forming applications. |

| International Organization for Standardization (ISO) | ISO 4948, ISO 3573 | – | Provides general definitions and classification of steels. |

Each of these standards specifies:

- Chemical composition (carbon, manganese, sulfur, phosphorus, etc.)

- Mechanical properties (yield strength, tensile strength, elongation)

- Dimensional tolerances and surface quality

- Test methods for impact resistance, hardness, and bendability

Conclusion

Hot rolled steel is a material of underlying construction, manufacture, and heavy industry due to its being economical, available in massive sizes, and highly workable. While it does possess constraints on surface finish and dimensional accuracy properties, these can often be overcome by follow-up treatments like pickling, galvanizing, or cold finishing. The most important steps for purchasers and specifiers are to select the correct standard and grade, insist on proper mill documentation, and inspect deliveries for performance and conformity.

FAQ

Q: What is the difference between hot rolled and cold rolled steel?

A: Hot rolled steel is processed at high temperature and has a rougher surface and wider tolerances; cold rolled is processed at room temperature (or reduced at cold temps) to produce a smoother finish and tighter dimensional control.

Q: Will hot rolled steel rust?

A: Yes — mill scale does not provide long-term corrosion protection. Apply galvanizing, painting, or oiling for protection.

Q: Can hot rolled steel be used for precision parts?

A: Not directly. For precision thickness, flatness, or surface finish, choose cold rolled steel or perform secondary machining/finishing.

Q: How do I verify the quality of hot rolled steel deliveries?

A: Require an MTC, inspect heat numbers, conduct visual surface checks, measure dimensions at multiple points, and request sample mechanical testing for critical applications.

Q: What thicknesses are typical for hot rolled steel?

A: Hot rolled products commonly range from about 1.5 mm up to 100+ mm for plates; coils and wide strips vary with mill capability.

Q: What post-processes are used with hot rolled steel?

A: Pickling (acid cleaning), galvanizing, annealing (rare), cold rolling (for improved tolerances), painting and powder coating.